Follower-Roller Design Arrangements

When the Follower-Profile in contact with the Cam-Profile is circular, we give it the term Follower-Roller. The Follower is the Part that supports the Follower-Roller.

Stud-type and Track-type Follower-Rollers

Generally, there are two types of Follower-Roller bearings:

•Stud

•Track

SKF cut-away views of Stud and Track type Follower Rollers

Both the Stud and Track types have many variants to suit different applications and working environments - axial guidance, type of lubrication, sealing, corrosion, use Ball or Roller/Needle rolling elements, etc. .

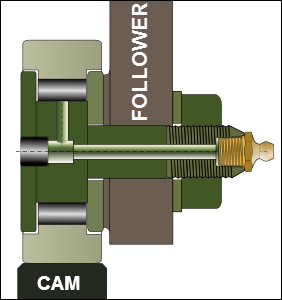

Stud-type Follower-Roller

Stud-type Follower-Roller

Stud Follower. The Stud is also the inner-race to the bearing. |

Stud Type Follower-Roller Most typically: •the stud is also the Follower-Roller bearing's inner-ring. •the nut pulls the side plate of the bearing against (a flange on the) Follower. •the are one or two sets of needle-rollers or balls. •they may have shields, seals, or neither. •they may have an eccentric sleeve to enable fine adjustments of the Follower-Roller axis. The adjustment is often used to eliminate/reduce backlash between the Follower-Roller and the Cam-Profile of conjugate cams. The Cam is typically 2-3mm wider than the Follower-Roller to prevent 'edge' stresses. |

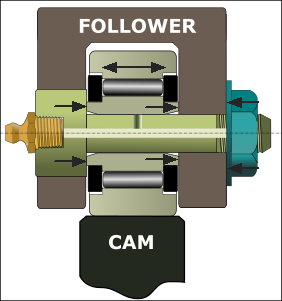

Track-type Follower-Roller

Track-type Follower-Roller

Preferred Yoke Mounting of Track Follower |

Track Type Follower-Rollers A Yoke (clevis, or fork) and Pin supports the Follower-Roller. In the image - the important detail is: •When the nut tightens (on the right), the shoulder of the support bolt (on the left) moves to the right and is forced against the left side of the bearing's inner-ring. This pulls the inner-ring up against the inside face of the right-hand fork of the yoke. Thus, the forks of the yoke do not deflect inwards when the nut is tight. The outer-ring of the Follower-Roller should not touch the Follower. The outer-ring can move axially, without restriction, by approximately 0.2mm. |

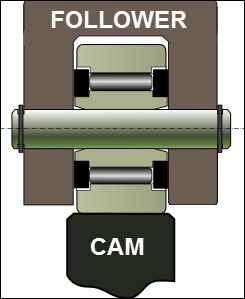

Acceptable Yoke Mounting of Track Follower |

•It is possible to use two circlips (snap-rings) to locate the support pin. •The inner-ring can move to the left or right and against the inside faces of the forks and yoke. •The outer-ring floats to the left or right, up against the flange-rings of the track bearing, and not the yoke. •The outer-ring should not touch the Follower.

|

Stud Follower-Rollers and Form-Closed Cams

Groove, or Track, Cams

Groove, or Track, Cams

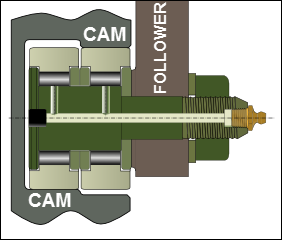

DESIGN 1: Typical Follower, with Stud, in a Cam-track. |

DESIGN 1: One bearing Follower-Roller To allow the Follower-Roller to rotate, the width of the cam-groove is greater than the diameter of the Follower-Roller bearing. Thus, the design has two disadvantages: 1.Backlash The clearance between the Follower-Roller and the Cam-Flanks, like any other backlash in the system, will cause impact forces (knocking) when the backlash is traversed. 2.Wear When the Follower-Roller moves from one Cam-Flank to the other, the Follower-Roller must rotate in the opposite direction. It cannot change its rolling direction instantly. Thus, it skids (slides) until it rolls along the Cam-Flank again. The skidding action wears the surfaces of the Follower-Roller and the Cam-Flank. |

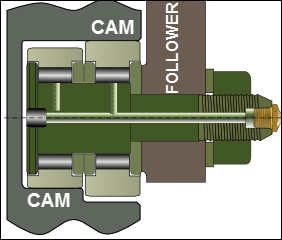

DESIGN 2A: Two, EQUAL diameter Stud Followers. The 'deeper' cam-track must be undercut. |

DESIGN 2: Two bearing Follower-Roller There are two Follower-Roller on the same stud / shaft. These designs aim to: 1. Reduce Backlash With good manufacturing tolerances, the backlash can be reduced. 2.Reduce Wear The Follower-Rollers do not need to change their rotational directions, and thus they do not scuff/wear as much as those Follower-Rollers that do need to change their rotational directions (see DESIGN 1)

DESIGN 2A: Two Follower-Roller - Equal Radius See image 'DESIGN 2A'. When the Follower-Roller diameters are equal, each roller must have a clearance between it and the non-working flank. There are four surfaces to machine: two working/active surfaces for the Follower-Roller to roll against, and two non-working/clearance surfaces to make sure the Follower-Roller do make contact.

DESIGN 2B: Two Cam-Rollers - Different Radius See image 'DESIGN 2B' The Cam-Flanks do not need to be undercut. It is easier to manufacture. Note: When the load is small, and the elimination of backlash is important, one roller can be steel and the other rubber. The rubber roller can be loaded against one cam flank to act as a spring to force the rigid roller against the other cam-flank and so act as a pre-load. Also applies to Conjugate and Rib cams. The pre-load force might be quite low. Example: Camera Lens. |

DESIGN 2B: Two, DIAMETER diameter Stud Follower. The deeper cam-track does not need to be undercut |

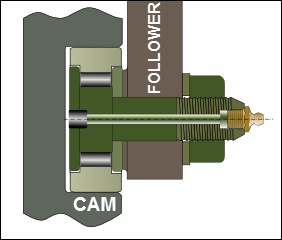

Conjugate-Cams

Conjugate-Cams

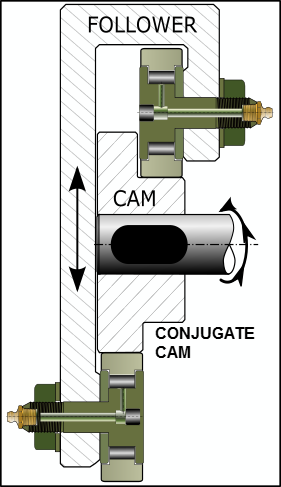

DESIGN 1: Typical Follower, with Stud, in a Cam-track. |

Conjugate Cams These have two Follower-Rollers, which are not on the same shaft/stud. Each Follower-Roller is at a different position in the Follower. Advantages: •The diameter of the Follower-Roller bearing can be different to suit the particular loading cycle. For example, the upper roller may support the weight loading and other forces, while the lower roller does not. •With accurate machining, backlash can be eliminated, •Care must be taken to make sure the bearings do not crush the cam at any point if any clearance becomes an interference as you rotate the cam. The mechanical-advantage to crush the cam is huge.

|