Cam and Mechanism Design with MechDesigner

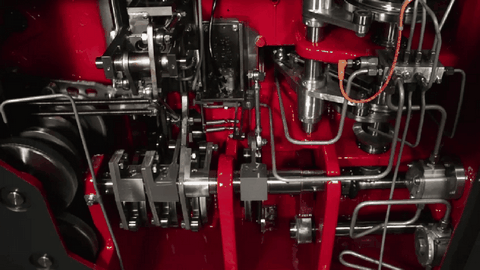

Example of cams in a protected enclosure with forced oil feed, typical of a packaging machine.

Even though there have been many advances in servo control in recent decades, cams are still important machine elements. There are many cam designs that servomotors cannot replace. Cam mechanisms are often preferred by designers on account of their apparent simplicity. Experienced design engineers know, however, that cam mechanisms are not always as simple as they seem. Considerable theoretical understanding is needed in order to get the best from a cam mechanism and avoid its premature failure. The performance of machines that appear to be identical can in fact be very different, and are entirely dependent on the quality of the cam system and motions. Those manufacturers who have the better knowledge will have machines that operate at higher speed, with greater reliability, and with lower maintenance costs, but at the same capital cost.

This section helps you understand how your design decisions can make a significant difference to the overall performance of a cam-system.