EXAMPLE 1: Input Transmission Rigidity

Design Arrangement of an Input Transmission - From the Drive Motor to the Cam. |

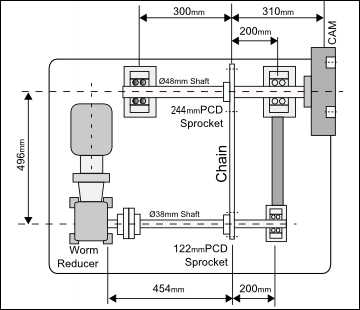

The cam-shaft is driven by a 2:1 reducing chain from a drive shaft, which is driven by a motor and worm gear-box. Find the overall rigidity of the input-transmission referred to the cam, from the output of the worm gear-box. Note: We want to find out how effectively the transmission is for the cam when it is driven by the worm gear-box. The shafts are made of medium carbon steel, and the chain and solid sprockets are steel. G = 82.5 x 109 N/m2 The coupling is sufficiently rigid in torsion, and the shaft mountings are stiff enough to be ignored in the calculation. The transmission chain is 0.5 inch pitch with a stiffness of 6 x 106N/m, for a 1m length. |

|||||||||||

Steps 1.Find the rigidity of each section of the transmission. 2.Refer the rigidities to the cam-shaft and cam. 1: Rigidity of the Drive Shaft: Torsion The drive shaft transmitting torque is , and long. Therefore its rigidity is:

The drive-shaft is connected to the cam-shaft by a reduction drive. referred to the Cam-Shaft

2: Rigidity of the Drive Shaft: Bending Calculate the Stiffness of the Drive-Shaft - Force to deflect it by a meter.

The Pitch Circle Radius of the Sprocket is . Therefore, equivalent torsional-rigidity of the drive-shaft at the drive-shaft (using Equation 3)

Finally, refer the Rigidity of the Drive Shaft to the Cam-Shaft via the reduction:

3: Rigidity of the Drive Chain From the drawing above: Length of chain that stretches under load = . Stiffness, for

The Pitch Circle Radius of the Chain-wheel is . Therefore, the rigidity of the chain referred to the cam-shaft is:

4: Rigidity of the Cam Shaft Bending

The Pitch Circle Radius of the Sprocket is . Therefore, the equivalent torsional rigidity is: (using Equation 3)

5: Rigidity of the Cam Shaft Torsion

Overall Torsional Rigidity of the Input Transmission

Comment: The most significant element with elasticity is the bending of the primary shaft. It has the lowest Rigidity, R2. This points to the possibility of a considerable improvement if: •The chain-drive could be moved closer to the right-hand bearing. and / or •the chain-sprocket could be increased in diameter. |

||||||||||||