LUBRICATION OF GEARS and CAMS

Methods of Lubrication

There are three lubrication methods in general use:

1.Grease lubrication.

2.Splash lubrication (oil bath method).

3.Forced oil circulation lubrication.

There is no single best lubricant and method. Choices depends upon speed (m/s) and rotating speed (rpm). At low speed, grease lubrication is a good choice. For medium and high speeds, splash lubrication and forced circulation lubrication are more appropriate, but there are exceptions. Sometimes, for maintenance reasons, a grease lubricant is used even with high speed. However, grease lubrication has limitations that prevent it from being used at 'very' high speeds.

The following is a brief discussion of the three lubrication methods.

Grease Lubrication

Grease lubrication is suitable for any gear or cam system that is open or enclosed. It is usually applied to low speed, or when the cam or gears are exposed to the product, pack, or packaging running on a machine. There are three major points regarding grease:

1.Choose a lubricant with suitable viscosity. A lubricant with good fluidity is especially effective in an enclosed systems.

2.Not suitable for use under high load and continuous operation. The cooling effect of grease is not as good as lubricating oil. So it may become a problem with temperature rise under high load and continuous operating conditions.

3.Proper quantity of grease. There must be sufficient grease to do the job. However, too much grease can be harmful, particularly in an enclosed system. Excess grease will cause agitation, viscous drag, a temperature rise, which will reduce the viscosity, and result in greater power loss thank lubricating oil.

Splash Lubrication

Splash lubrication is used with an enclosed system. The rotating cams and gears splash lubricant onto the gear system and bearings. It needs at least 3 m/s tangential speed to be effective. However, splash lubrication has several problems, two of them being oil level and temperature limitation.

1.Oil level.

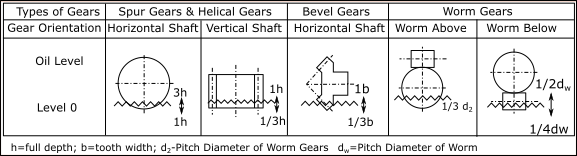

There will be excessive agitation loss if the oil level is too high. On the other hand, there will not be effective lubrication or ability to cool if the level is too low. Table 2 shows guide lines for proper oil level. Also, the oil level during operation must be monitored, as contrasted with the static level, in that the oil level will drop when the cams and gears are in motion. This problem may be countered by raising the static level of lubricant or installing an oil pan.

2.Temperature limitation.

The temperature of an enclosed system may rise because of friction loss due to any gears, bearings and lubricant agitation. Rising temperature may cause one or more of the following problems:

oLower viscosity of lubricant.

oAccelerated degradation of lubricant.

oDeformation of housing, gears and shafts.

oDecreased backlash.

New high-performance lubricants can withstand up 90°C. This temperature can be regarded as the limit. If the lubricants temperature is expected to exceed this limit, cooling fins should be added to the gear box, or a cooling fan incorporated into the system.

Forced-Circulation Lubrication

Forced-circulation lubrication applies lubricant to the contact portion of the teeth by means of an oil pump. There are drop, spray and oil mist methods of application.

1.Drop method:

An oil pump is used to suck-up the lubricant and then directly drop it on the contact portion of the gears via a delivery pipe.

2.Spray method:

An oil pump is used to spray the lubricant directly on the contact area of the gears.

3.Oil mist method:

•Lubricant is mixed with compressed air to form an oil mist that is sprayed against the contact region between the cam and cam-roller, and between gears. It is especially suitable for high-speed machines.

•Oil tank, pump, filter, piping and other devices are needed in the forced-lubrication system. Therefore, it is used only for special high-speed or large gear box applications. By filtering and cooling the circulating lubricant, the right viscosity and cleanliness can be maintained. This is considered to be the best way to lubricate cams and gears.

Cam Lubricants

An oil film must be formed at the contact surface between the Cam-Profile and Follower-Roller to minimize friction and to prevent dry metal-to-metal contact. The lubricant should have the properties listed in Table 3.

Also, the Oil Viscosity is dependent on the ambient temperature and the operating speed.

Viscosity of Lubricant

The correct viscosity is the most important consideration in choosing a lubricant.

•Table 4 expresses ISO viscosity grade of industrial lubricants.

•Table 5 shows the classes and viscosity of industrial gear oils.

•Table 6 shows the NLGI classes of greases

•Table 7 contains AGMA viscosity grades and their equivalent ISO viscosity grades.

Selection of Lubricant

It is practical to select a lubricant by following the catalog or technical manual of the manufacturer.

• Table 8 is the application guide from AGMA 250.03 "Lubrication of Industrial Enclosed Gear Drives".

•Table 9 is the application guide chart for worm gears from AGMA 250.03.

•Table 10 expresses the reference value of viscosity of lubricant used in the equations for the strength of worm gears in AGMA 405-01.

Input shaft speed (RPM) |

0-20 |

20-100 |

100-200 |

200-300 |

300-400 |

>400 |

|---|---|---|---|---|---|---|

Lubricant Viscosity cSt @ 40 degrees C |

>680 |

680-460 |

460-320 |

320-220 |

220-150 |

15-=68 |

Typical Viscosity grade for precision indexing drives.

Note: Heinz-Automation recommends Klübersynth GH 6-460 Synthetic gear and high temperature oils for its enclosed cam indexers.

TABLES:

Table 1: Range of Typical Speed (m/s) for Spur and Bevel Gears

No |

Lubrication Type |

Range of Tangential Speeds (m/s) |

|||||

0 |

5 |

10 |

15 |

20 |

25 |

||

1 |

Grease |

|

|

|

|

|

|

2 |

Splash |

|

|

|

|

||

3 |

Forced Circulation |

Applies to 'Oil Mist', Circulating Oil, 'Oil Jets'. |

|

||||

Table 2: Oil Levels for different Gear Types

Table 3: The Properties that Lubricant Should Possess

No. |

Properties |

Description |

1 |

Correct and Proper Viscosity |

Lubricant should maintain a proper viscosity to form a stable oil film at the specified temperature and speed of operation. |

2 |

Anti-scoring Property |

Lubricant should have the property to prevent the scoring failure of tooth surface while under high-pressure of load. |

3 |

Oxidization and Heat Stability |

A Good lubricant should not oxidized easily and must perform in moist and high-temperature environment for long duration. |

4 |

Water Anti-affinity Property |

Moisture tends to condense due to temperature change, when the gears are stopped. The lubricant should have the property of isolating moisture and water from lubricant. |

5 |

Anti-foam Property |

If the lubricant foams under agitation, it will not provide a good oil film. Anti-foam property is a vital requirement. |

6 |

Anti-corrosion Property |

Lubrication should be neutral and stable to prevent corrosion from rust that may mix into the oil. |

Table 4: ISO Viscosity Grade of Industrial Lubricant - ISO 3448

The correct viscosity is the most important consideration in choosing a proper lubricant. The viscosity grade of industrial lubricant is regulated ISO 3448.

ISO |

Viscosity Grade ISO 3448 |

Kinematic Viscosity Center Value 10-6m²/s (cSt) (40ºC) |

Kinematic Viscosity Range 10-6m²/s (cSt) (40ºC) |

|

More Than |

Less than |

|||

ISO VG |

2 |

2.2 |

1.98 |

2.42 |

ISO VG |

3 |

3.2 |

2.88 |

3.52 |

ISO VG |

5 |

4.6 |

4.14 |

5.06 |

ISO VG |

7 |

6.8 |

6.12 |

7.48 |

ISO VG |

10 |

10 |

9 |

11.0 |

ISO VG |

15 |

15 |

13.5 |

16.5 |

ISO VG |

22 |

22 |

19.8 |

24.2 |

ISO VG |

32 |

32 |

28.8 |

35.2 |

ISO VG |

46 |

46 |

41.4 |

50.6 |

ISO VG |

68 |

68 |

61.2 |

74.8 |

ISO VG |

100 |

100 |

90 |

110 |

ISO VG |

150 |

150 |

135 |

165 |

ISO VG |

220 |

220 |

198 |

242 |

ISO VG |

320 |

320 |

288 |

352 |

ISO VG |

460 |

460 |

414 |

506 |

ISO VG |

680 |

680 |

612 |

748 |

ISO VG |

1000 |

1000 |

900 |

1100 |

ISO VG |

1500 |

1500 |

1350 |

1650 |

Table 5: Industrial Gear Oil

Types of Industrial Gear Oil |

Usage |

|

Class One |

ISO VG 32 ISO VG 46 ISO VG 68 ISO VG 100 ISO VG 150 ISO VG 220 ISO VG 320 ISO VG 460 |

Mainly used in a general and lightly loaded enclosed gear system |

Class Two |

ISO VG 68 ISO VG 100 ISO VG 150 ISO VG 220 ISO VG 320 ISO VG 460 ISO VG 680 |

Mainly used in a general medium to heavily loaded enclosed gear system |

Table 6: NLGl Viscosity Grades

NLGI No. |

Viscosity Range |

State |

Application |

No 000 |

445...475 |

Semi-Liquid |

For Central Lubrication Systems |

No 00 |

400...430 |

Semi-Liquid |

|

No 0 |

335...385 |

Very Soft Paste |

Automotive Chassis |

No 1 |

310...340 |

Soft Paste |

|

No 2 |

265...295 |

Medium Firm Paste |

Ball and Roller Bearing General Use |

No 3 |

220...250 |

Semi-hard Paste |

|

No 4 |

175...205 |

Hard Paste |

Sleeve Bearing (Pillow Block)Automobile Wheel Bearing |

No 5 |

130...165 |

Very Hard Paste |

|

No 6 |

85....115 |

Very Hard Paste |

Table 7: AGMA Viscosity Grades

AGMA No. of Gear Oil (ASTM D2422 / AGMA 9005-D94) |

~ ISO Viscosity Grades |

|

R & O Type |

EP Type |

|

0 |

|

VG 32 |

1 |

|

VG 46 |

2 |

2 EP |

VG 68 |

3 |

3 EP |

VG 100 |

4 |

4 EP |

VG 150 |

5 |

5 EP |

VG 220 |

6 |

6 EP |

VG 320 |

7 C |

7 EP |

VG 460 |

8 C |

8 EP |

VG 680 |

8A comp, |

9EP |

VG 1000 |

https://wiki.anton-paar.com/uk-en/agma-viscosity-classification/ |

||

Table 8 Recommended Lubricants by AGMA

It is practical to select a lubricant by following the catalog or technical manual of the manufacturer. This table is the application guide from AGMA 250.03 "Lubrication of Industrial Enclosed Gear Drives".

Gear Type |

Size of Gear Equipment (mm) |

Ambient temperature ºC |

|||

-10 ... 16 |

10 ... 52 |

||||

AGMA No. |

|||||

Parallel Shaft System |

Single Stage Reduction |

Center Distance (Output Side) |

Less than 200 200 ... 500 more than 500 |

2 to 3 2 to 3 3 to 4 |

3 to 4 4 to 5 4 to 5 |

Double Stage Reduction |

Less than 200 200 ... 500 More than 500 |

2 to 3 3 to 4 3 to 4 |

3 to 4 4 to 5 4 to 5 |

||

Triple Stage Reduction |

Less than 200 200 ... 500 More than 500 |

2 to 3 3 to 4 4 to 5 |

3 to 4 4 to 5 5 to 6 |

||

Planetary Gear System |

Outside Diameter of Gear Casing |

Less than 400 More than 400 |

2 to 3 3 to 4 |

3 to 4 4 to 5 |

|

Straight and Spiral Bevel Gearing |

Cone Distance |

Less than 300 More than 300 |

2 to 3 3 to 4 |

4 to 5 5 to 6 |

|

Gear-motor |

2 to 3 |

4 to 5 |

|||

High Speed Gear Equipment |

1 |

2 |

|||

Table 9 Recommended Lubricants for Worm Gears by AGMA

Types of Worm |

Center Distance mm |

Speed of Worm RPM |

Ambient Temperature ºC |

Speed of Worm RPM |

Ambient Temperature, ºC |

||

-10 ... 6 |

10 ... 52 |

-10 ... 16 |

10 ... 52 |

||||

Cylindrical Type |

<150 150 ... 300 300 ... 460 460 ... 600 600< |

700< 450< 300< 250< 200< |

7 Comp |

8 Comp |

700< 450< 300< 250< 200< |

|

8 Comp |

7 Comp |

|

||||||

Throated Type |

<150 150 ... 300 300 ... 460 460 ... 600 600< |

700< 450< 300< 250< 200< |

8 Comp |

8A Comp |

700< 450< 300< 250< 200< |

8 Comp |

|

Quick, subjective but important tests of the lubricant

There are several simple tests that can be performed on-site and at low cost to check for contamination or oxidation of the lubricant. The tests should be performed by the same person each time, because the tests require experience to accurately judge the results.

The tests can be run as often as necessary, but they should be done every time samples are taken for laboratory analysis.

Appearance Test: The simplest test is visual appearance. Often, this test will disclose problems such as gross contamination or oxidation. Look at the lubricant in a clean, glass bottle. A narrow, tall vessel is best. Compare the sample with a sample of new, unused lubricant. The oil should look clear and bright. If the sample looks hazy and cloudy, or has a milky appearance, there may be water present. The color should be similar to that of the new oil sample. A darkened color may indicate oxidation or contamination with wear particles. Tilt the bottle and observe whether the used oil appears more or less viscous than the new oil. A change in viscosity may indicate oxidation or contamination. Look for sediment at the bottom of the bottle. If any is present, .run the sedimentation test.

Sniff Test: Carefully sniff the oil sample. Compare the smell of the used oil sample with that of new oil.b, The used oil should smell the same as new oil; that is, it should have a bland, oily odor. Oils that have oxidized have a "burnt" odor, or smell acrid, sour, or pungent.

Sedimentation Test: If any sediment is visible during the appearance test, a simple test for contamination can be performed on site as follows: place a sample of oil in a clean, white, plastic cup and allow it to stand for 2 days. Carefully pour off all but a few milliliters of oil. If any particles are visible at the bottom of the cup, contaminants are present.

Resolution of the unaided eye is about 40μm. If particles respond to a magnet under the cup, iron or magnetite wear fragments are present; if they don't respond to the magnet, and the solids feel gritty between the fingers, they are probably sand. If another liquid phase is visible, or the oil appears milky, water is probably present.

Crackle Test: If you suspect there may be water present in an oil sample, you should perform a simple test for water contamination that can be performed on site as follows: drop a small drop of oil onto a hot plate at 135°C (275°F). If the sample bubbles, water is above 0.05%. If the sample bubbles and crackles, water is above 0.1 %

Mineral oils

Obtained from the distillation of crude petroleum, these oils are complex mixtures of organic and inorganic compounds and can be distinguished by their chemical composition [4]. These oils can be paraffinic, naphthenic, aromatic.

The aromatic fraction is usually undesirable and can be found in small proportions. Therefore, these

are least used in the lubrication, while the paraffinic and naphthenic based oils are

widely used due to their low cost and reasonable performance.

•Paraffinic - characterized by its high-level fluidity point, high viscosity index, good oxidation resistance, good oiliness and high amount of carbon residue;

•Naphthenic - opposed to the paraffinic, these oils present low level fluidity point, low viscosity index, low oxidation resistance, large oiliness and low amount of carbon residue;

•Mixed: Manufactured using paraffinic and naphthenic base oils, these are widely used, exhibiting a large range of viscosity grades, low volatility, resistance to deterioration and also protection against corrosion [4].

synthetic Oils

Synthetic lubricants are obtained by synthesis of light hydrocarbons with the inclusion of some non-petroleum organic elements. These lubricants have some benefits, such as increased oil longevity, better heat resistance, and they are better for the environmentally. They have, however, a higher cost. Even so, these oils have been widely used in aviation and industrial application for many years now.

These oils are generally obtained starting with a synthetic base obtained from petroleum and then other compounds are added to match the desired viscosity and other required properties. This way, they become more expensive but present better performance than the mineral oils, being specific the application in hand.

Synthetic oils can be grouped in the following categories:

•Polyalphaolefins (PAO) - are the most common synthetics base lubricants. Although they are bad additive solvents, they have a low fluidity point, good thermal stability and a high viscosity index;

•Polyglycols (between which the Polyalkalineglycol - PAG) - characterized by their low friction coefficient, they are ideal for high sliding applications where the friction is very strong;

•Esters - a wide class of lubricants. Each ester has several different properties as the good behavior at low temperatures, the high thermal resistance and the fact that most of them are biodegradable, making its class of vital importance for many gear oil formulations aiming to be classified biodegradable.

Greases

A grease is defined as the "dispersion of a thickening agent in a lubricating oil". The thickening agents can be of two types:

•Soaps - Aluminum, Barium, Calcium, Lithium, Sodium and Strontium.

•No soap - Organic clays, Polyureas, Inorganic compounds.