This application is a simple and cheap indexer. However, the output has motion-discontinuities. Therefore, I would not use it for a high-speed machine unless the load inertia is small.

Add an Orbiting Pulley and edit the length of the Belt

|

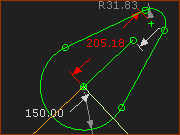

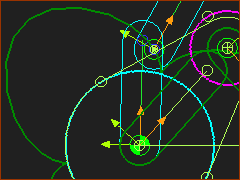

STEP 1: Do Orbiting Pulley center STEP 2: Add a Trace-Point to the Motion-Point.

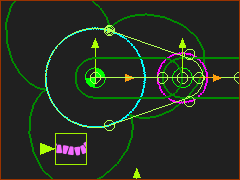

The Motion-Point moves along the Trace-Point. To construct a 3-Stop Indexer, the Trace-Point must trace exactly three lobes (flower-petals) around the fixed Pulley. |

||||

|

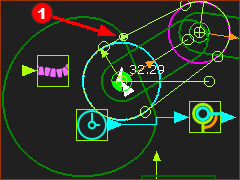

STEP 3: Add a Gearing FB to increase the number of rotations of the Crank

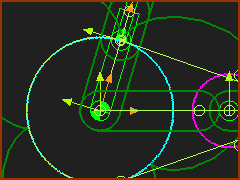

The Trace-Point has more lobes. However, the Trace-Point does not end where it starts. Edit these parameters in these elements: •Pulley : Number of Teeth •Motion-Path FB : Length of the Belt, Tooth-Pitch STEP 4: Edit each Pulley

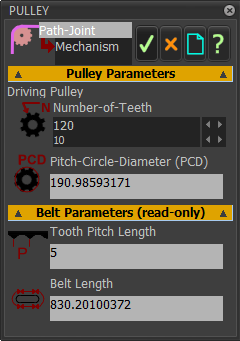

Note The read-only parameters in the Pulley dialog

|

||||

Pulley dialog: Number-of-Teeth |

|||||

Motion-Path dialog  Motion-Path FB |

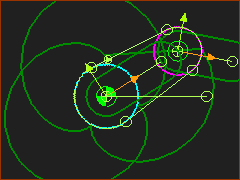

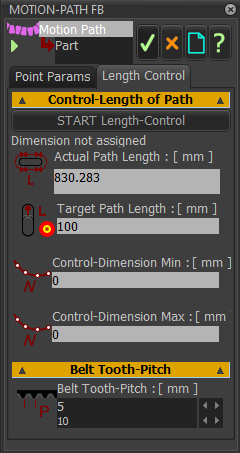

STEP 5: Edit the Motion-Path FB.

|

||||

STEP 6: Select a Control-Dimension We must select a dimension with which the dialog can control the length of the Belt.

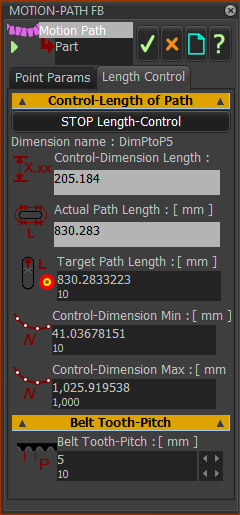

STEP 7: Review the Motion-Path dialog

|

|||||

|

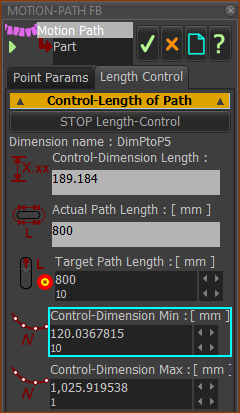

STEP 8: Edit the Target Path Length parameter I want the Actual-Path-Length = 800mm.

|

||||

|

When the Target Path Length = 800mm, you will see Trace-Point of the Motion-Point has three lobes. |

||||

Add a R-P-R dyad.

|

Add a R-P-R dyad Remember: all dyads have 2 × Parts and 3 × Joints. An R-P-R dyad has two Pin-Joints(R-×-R) and one Slide-Joint (×-P-×) STEP 1: Add two Parts and two Pin-Joints:

|

||

|

STEP 2: Add a Slide-Joint between then CAD-Lines of the two new Parts.

STEP 3: Cycle the mechanism (use the ALT+C keyboard combination).

|