Add a 2D-Cam and Configure the Power Source

When we add a 2D-Cam, and we want to know the Contact-Force, Maximum Shear-Stress, and Life of the Follower-Roller and/or Cam-Profile, we must also Configure the Power Source.

In this Step 13.4, we will:

1.Delete the Spring FB.

2.Delete the wire between the output-connector of the Linear-Motion FB and the input-connector of the Motion-Dimension FB.

3.Do and to extrude the 2D-Cam as an MD-Solid (Note, not required for Contact-Force).

4.Use Configure the Power Source to move the Power-Source from the Follower's Pin-Joint / rotating-axis to the 2D-Cam. |

Add a Follower-Roller

|

Add a Follower-Roller to the Rocker.

1.Edit the Rocker, Add a Circle (100 Radius), Add Coincident to move its center-Point to the end-Point of the Rocker, Close the Part-Editor.

2.Add a Profile to the Circle.

3.Edit the Density of the Profile/Extrusion until its mass is ~1kg. The Follower Profile:

•Weighs 10N (a mass ~1kg)

•Center-of-mass (the center of the Circle) is 200mm, horizontally, from the Pin-Joint. |

|

|

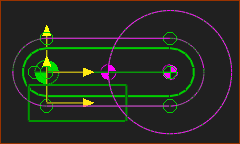

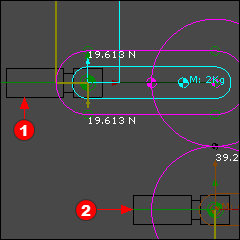

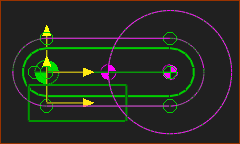

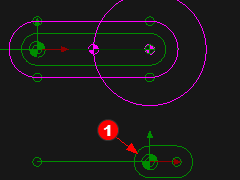

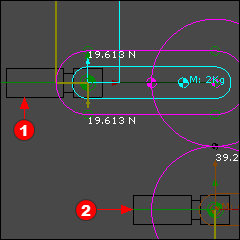

The image is the end of the Rocker.

Note: there are three symbols that identify the:

Center-of-mass of the original Profile (1kg @100,0) Center-of-mass of the original Profile (1kg @100,0)

Center-of-mass of the Follower-Roller Profile (1kg @200,0) Center-of-mass of the Follower-Roller Profile (1kg @200,0)

Center-of-mass of all of the Profiles in the Part / Rocker (2kg, @150mm). It has a color that matches the color of the Part-Outline. Center-of-mass of all of the Profiles in the Part / Rocker (2kg, @150mm). It has a color that matches the color of the Part-Outline.

|

|

|

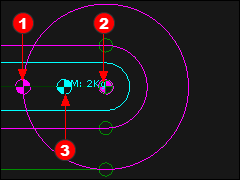

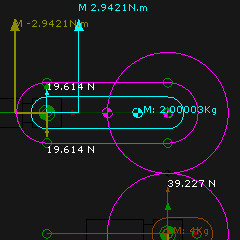

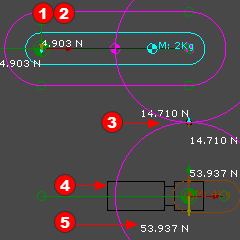

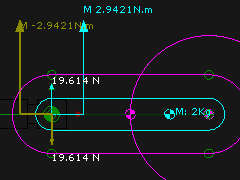

Forces and Moments with a Profile 1kg @ x=100mm, y=0, and a Follower-Roller Profile of 1kg @ x=200mm, y=0

Forces:

∑ Vertical Forces acting on the Rocker (+ is Up)

-(1(kg) + 1(kg))* 9.81(m/s/s) = -19.62N (Down)

∴ Reaction Force from the Base-Part that acts on the Rocker is +19.62N (Up).

|

Moments:

∑ Moments acting on the Rocker (+ is Anti-Clockwise)

-1(kg)*9.81(m/s^2)*0.1(m) - 1(kg)*9.81(m/s^2)*0.2(m) = –2.943Nm (Clockwise Moment)

∴ Reaction Moment from the Base-Part that acts on the Rocker = +2.943Nm (Anti-clockwise).

|

|

Add a Cam-Part and 2D-Cam

|

Disable Force Vectors: Display temporarily, to hide the Force Vectors, while we add a Part for the cam.

STEP 1:Add a Cam-Part

1.Edit the Base-Part, Add a horizontal Line. The end-Point of the Line is at 200,–200 mm

2.Add a Part - the Cam-Part

3.Add a Pin-Joint. Click the start-Point of the Part and the end-Point of the Line.

4.Add a Motion-Dimension FB to control the angle of the Cam-Part

5.Add a Linear-Motion FB to control the rotation of the Cam-Part |

|

|

STEP 1:Add 2D-Cam

|

1.Click > |

a.Click the Cam-Part

b.Click the Follower Profile |

The 2D-Cam is circular because the Follower-Roller does not move. is circular because the Follower-Roller does not move.

STEP 2:Hide the Outer Cam

1.Double-click the 2D-Cam in the graphics-area to open the 2D-Cam dialog.

2.Click the Display tab > Cam Profile Display > . |

|

Add Mass to the Cam a Mass

Note: We do not need to add mass the Cam a Mass. However, it is a good opportunity to remind you of how you can, if you really want to, do and . to extrude the 2D-Cam as a Solid.

|

|

STEP 1: Add a Polyline to the 2D-Cam

|

1.Click the Home key on your keyboard

2.Click - see icon to the left

3.Click the 2D-Cam

4.Click  in the Command-Manager in the Command-Manager |

The Polyline is superimpose over the 2D-Cam.

STEP 2: We can add a Profile to a Polyline

|

1.Click - see icon to the left

2.Click the Polyline - it is superimposed over the 2D-Cam

3.Click  in the Command-Manager in the Command-Manager |

|

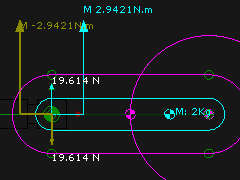

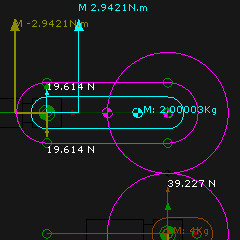

You can see the force and moment that act on the Rocker are the same as before, 19.61N and 2.942Nm, respectively.

The Problem : Where is the Contact Force between the Cam and Follower?

For convenience, the mass of the 2D-Cam equal 4kg . To edit the mass, edit the or of the Extrusion

Therefore, there is a Force that acts on the 2D-Cam of 39.227N.

|

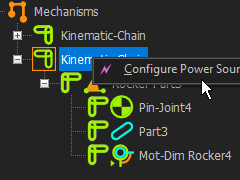

Configure the Power Source

|

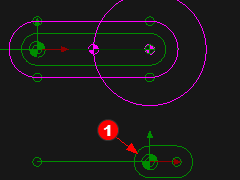

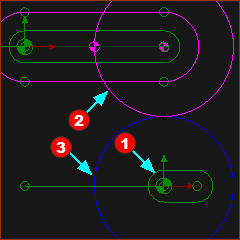

Why is the Contact Force between the Cam and the Cam-Profile equal to zero?

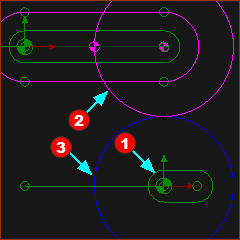

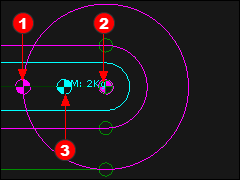

In the image to the left, there are two Power Source (2 Motors ) )

•Motor drives the Rocker drives the Rocker

•Motor drives the Cam-Part drives the Cam-Part

There is usually ONE motor to drive a Cam mechanism! This is because:

•Motor does not exist. The 2D-Cam drives the Follower / Rocker, and not a motor. does not exist. The 2D-Cam drives the Follower / Rocker, and not a motor.

•Motor is OK. It drives the Cam-Part. is OK. It drives the Cam-Part. |

We must Configure the Power Source to make the 2D-Cam drive the Follower / Rocker.

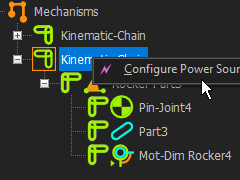

STEP 1: To open the Configure Power Source dialog:

In the Kinematics-Tree, do these three(3) clicks

a)Click the Kinematic-Chain that includes the Follower

b)Right-Click the Kinematic-Chain

c)Click Configure Power Source

or

|

|

a)Click the kinematic-chain with the Follower

b)Click |

|

|

|

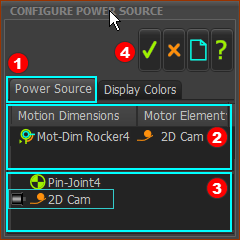

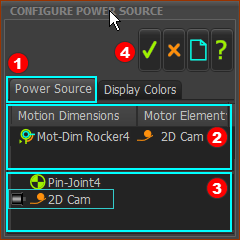

In Configure Power Source dialog is now open.

STEP 2: Select the Power-Source in the Configure Power Source

Click the Power Source tab Click the Power Source tab

Click Mot-Dim Rocker Click Mot-Dim Rocker

Mot-Dim Rocker is the Motion-Dimension we want to drive with a Power-Source

The default Power Source is Pin-Joint.

Click the 2D-Cam Click the 2D-Cam

2D-Cam is now Power-Source to drive the Motion-Dimension ( Mot-Dim Rocker) Mot-Dim Rocker)

The  icon (a small motor) is now to the left of the 2D-Cam icon (a small motor) is now to the left of the 2D-Cam to indicate it is the Power-Source. to indicate it is the Power-Source.

The 2D-Cam is the Motor Element to the right of Mot-Dim Rocker.

Click Click  to close the dialog to close the dialog

|

|

|

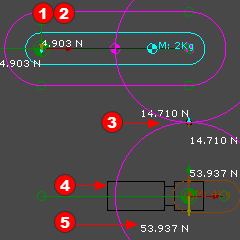

You should see that:

1.The Motor symbol is not at the Pin-Joint of the Follower / Rocker

2.There is not a Torque vector at the Follower Pin-Joint . .

3.Action and reaction forces at the Cam Contact

4.The Motor symbol at the Cam-Shaft

5.The Action and Reaction Forces at the center of the 2D-Cam are now 53.94N,

The center of the 2D-Cam must support the weight (m*g) of the Follower/Rocker and the Follower-Roller

The 2D-Cam does not need a torque because it does not do useful work. The 2D-Cam simply supports the mass of the Follower and Follower-Roller.

|

|