Linear Stiffness, Torsional Stiffness, Bending Stiffness

The dynamics is a function of the units from the output of the Motion-Dimension FB that controls the motion of the kinematics model. If the:

Motion-Dimension controls an Angular dimension (Rocker): refer the stiffness and damping of each body/part in a mechanism to a single Torsional Stiffness and Damping-Coefficient at the Rocker joint that you control with the Motion-Dimension.

Motion-Dimension controls a Linear dimension (Slider): refer the stiffness and damping of each body/ part in a mechanism to a single Linear Stiffness and Damping-Coefficient at the Slider joint that you control with the Motion-Dimension.

To find the overall Stiffness, we recommend that you do a simple FEA analysis of each part and also the assembly, in your model.

Alternatively, you must calculate/approximate the:

•Bending Stiffness of an Oscillating Follower

•Bending of Transmission Levers, such as Bell Cranks

•Linear Stiffness of a Reciprocating Follower

•Linear Stiffness (elongation) of a Part in tension or compression.

•Use the lever law to evaluate the Equivalent Stiffness at the Follower or the Tool. See Online Manual.

•Torsional Stiffness of transmission shafts.

It is important to include the 'lever-law', which applies the square of the linear amplification ratio of displacements, to reference the mass, inertia, damping, and stiffness across a 'bell-crank' type lever.

Also, to convert a Torsional Stiffness to a Linear Stiffness means you must use the Lever law.

Damping

Damping is difficult. Damping can be regarded as the loss of energy. However, the positive effect of damping is that it damps vibration.

Damping Prediction

The damping of mechanical systems is hard to predict.

Rule of thumb: Damping decreases with increasing frequency.

Joint and other system impurities increase damping.

with the viscous damping ratio, .

System |

[-] |

Metals in their elastic range |

0.01 |

Continuous metal structures |

0.02 - 0.04 |

Metal structures with joints |

0.03 - 0.07 |

Plastics (Hard - Soft) |

0.02 - 0.05 |

Rubber |

0.05 |

Sintered material (piezos) |

0.07 |

Air dash-pots (vibration isolation tables) |

0.07 |

Estimating damping coefficients

This involves analyzing a system's free decay, typically through experimental methods like measuring the logarithmic decrement of free oscillations. For a simple viscous damping, if you know the stiffness and mass of the system and can measure the decay, you can determine the damping coefficient by finding the damping ratio and then calculating the coefficient (c) using the formula: .

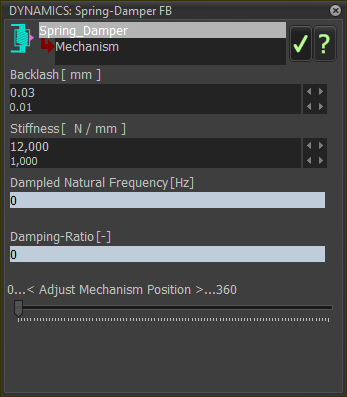

Spring-Damper dialog