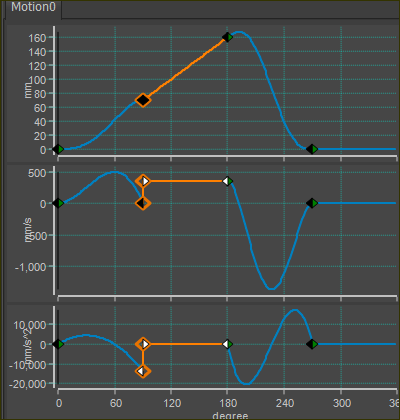

Because we cannot select the Match-Velocity or Match-Acceleration or the Match-Jerk Control-Buttons for this 'special' motion-law, we must manually make sure the actual velocity, and Acceleration and Jerk motion-values are equal to those of this 'special segment', if we want motion-continuity.

To make sure there motion-values of position, velocity, acceleration, (and optionally jerk) are continuous from the Previous-Segment and to the Next-Segment:

1.Take note of the Velocity* (read-only) of this Constant-Velocity: Two Position segment

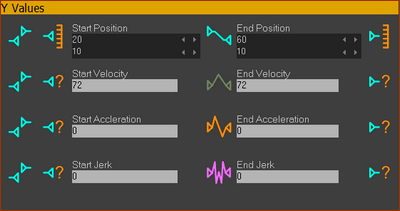

2.Select the Previous-Segment before this Constant-Velocity: Two Position segment

3.Make active the End-Velocity, End-Acceleration, End-Jerk Control Buttons

4.Enter the Velocity* (noted in 1) in the End-Velocity data-box

5.Enter 0 in the End-Acceleration and optionally End-Jerk data-boxes

6.Select the Next-Segment after this Constant-Velocity: Two Position segment

7.Make sure the Match-Position, Match-Velocity, Match-Acceleration, (and optionally Match-Jerk) Control-Buttons are active. |