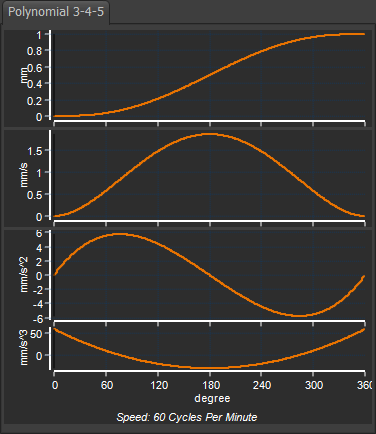

Dynamic Performance

This Motion-Law is recommended for applications where the period ratio is less than 10, particularly where the input drive is stiff and the shaft speed does not fluctuate significantly under load.

It has good acceleration characteristics and is suitable for applications that need low levels of residual vibration.

Pressure Angle Considerations

This is a Traditional Motion-Law that produces a relatively large pressure angle - and so might need a larger cam for a given lift and pre-prescribed maximum pressure angle.

Drive Torques

The torque characteristics of this motion law are good compared to other traditional motion-laws, when the period ratio is less than 10. IT is recommended when no sudden change in torque is allowed.

|