Continuous-Crank

See also Add Continuous-Crank

Usually, in a multi-part mechanism, you design the motion for a Tool-Part (the Part with the tooling), and we use Inverse-Kinematics to calculate the motion of a follower or a servomotor. The follower usually oscillates or reciprocates. A servomotor may also oscillate. However, there is also the case in which the servomotor rotates completely, but with a non-uniform rotating speed. This is a special-case. To enable this special-case, the rotating part must be the correct length, and its motion, also derived by inverse-kinematics from the motion of the Tool-Part, is more complex. This is one application of the Continuous-Crank FB. |

How to open the Continuous-Crank FB dialog

|

To open the Continuous-Crank dialog:

|

The Continuous-Crank dialog is now open.

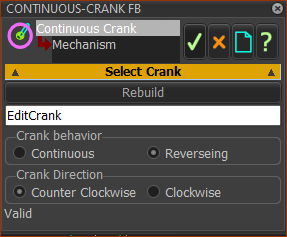

Continuous-Crank dialog

Continuous-Crank dialog - not enabled |

STEP 1: Select Crank Behavior and Direction Crank Behavior

Crank Direction

|

|||||||||||

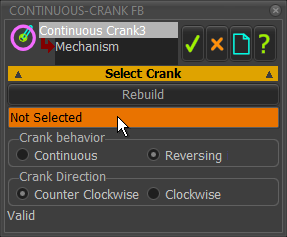

Continuous-Crank dialog- enabled |

STEP 2: Activate the Not Selected box

STEP 3: Click a Part that you want to be the Continuous-Crank

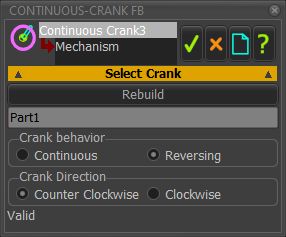

The Part immediately changes its length so that it can rotate continuously or oscillate by 180º. If there is a problem, see Messages at the bottom of the dialog. STEP 4: Confirm the behavior is as expected

STEP 5: Click Messages at the bottom of the dialog: When you select a Part as the Continuous Crank, there is be a message at the bottom of the dialog.

|

|||||||||||

Continous-Crank dialog |