Note:

When you open these dialogs, you may need to click the button two times to size the dialog correctly. |

To open the Edit Joint dialog:

Make sure •Forces Vectors: Calculate is active in the Forces menu •A Force acts on the Points at the Joint. Then: 1.Double-click a pin-Joint or Slide-Joint in the graphics-area OR 2.See How to Open a dialog |

Nothing happens if you double-click the joint and also a different element. For example, if you double-click the Pin-Joint and a Point.

TOP-TIP:

Use Selection-Filters to filter for Joints only. |

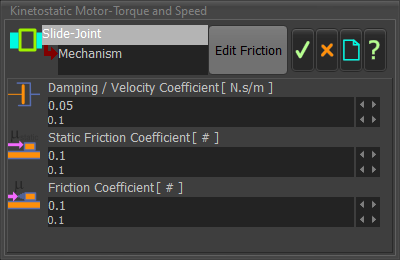

Slide-Joint dialog

•Damping/Velocity Coefficient:

Apply a force opposite and proportional to the velocity.

Friction Force

In a Slide-Joint, the friction force is the resistance to motion when one surface slides against another. This force acts parallel to the surfaces in contact and opposite to the direction of motion or intended motion. The specific type of friction depends on whether the joint is at rest or in motion.

Static Friction Coefficient

This is the force that prevents the joint from moving initially. Strictly, it is a variable force that can match any applied force up to a maximum limit. The joint will not move until the applied force exceeds this maximum static friction.

From a kinetostatic viewpoint, in which we impose motion on the Parts along the Slide-Joint, the force that is needed to start the body moving is.

In MechDesigner, Force vectors radiate from the Points at each end of the Lines in the Slide-Joints, and normal (right-angle) to the Lines.

When you apply a Friction Coefficient, the vectors are not normal to the Lines.

Static-Friction is sometimes called “Stiction” or “Breakaway Friction”.

Kinetic Friction Coefficient

Also known as sliding friction, this is the force that resists motion once the joint is sliding. The force of kinetic friction is typically less than the maximum static friction, which is why it is often easier to keep an object sliding than to start it sliding.

From a kinetostatic viewpoint, in which we impose motion on the kinematic-chain, the force that is needed to keep the body moving is.

In MechDesigner, Force vectors radiate from the Points at each end of the Lines in the Slide-Joints, and normal (right-angle) to the Lines.

When you apply a Kinetic Friction Coefficient, the vectors are normal to the Lines.

Damping and Friction Coefficients for a Slide-Joint

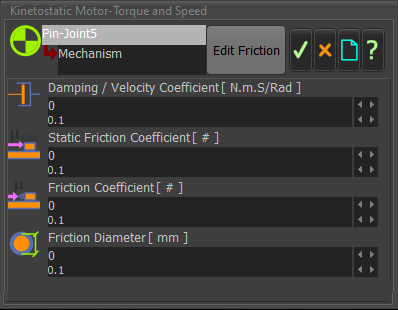

Pin-Joint dialog

•Damping/Velocity Coefficient

•Static Friction Coefficient

•Kinetic Friction Coefficient

•Friction-Diameter

Damping and Friction Coefficients for a Pin-Joint

Estimates of Damping

The damping coefficient for a Pin-Joint rod-end bearing is generally low, especially in dry or poorly lubricated conditions. It can range from very low values (around 0.001-0.005,

e.g., 0.25 x 10e-5 x Kxx for rolling element bearings) to moderate values (e.g., 330-550 Ns/m for dry deep groove ball bearings). The presence of even a small amount of lubricant significantly increases the damping, with values potentially reaching 1800-2100 Ns/m.

Examples:

•Dry or poorly lubricated:

In these conditions, damping is primarily due to friction between the moving parts. For rolling element bearings, damping coefficients can be very low, often in the range of 0.25 to 2.5 x 10e-5 times the stiffness (Kxx or Kyy).

•Lubricated:

Even a small amount of lubricant can drastically increase damping. For example, deep groove ball bearings with lubricant can have damping coefficients from 1800 to 2100 Ns/m, according to SKF Evolution.

Factors Affecting Damping:

•Lubrication: The type and amount of lubricant significantly impact damping.

•Bearing type: Different bearing types (e.g., ball bearings, roller bearings) will have different damping characteristics.

•Load: The load on the bearing can affect the friction and thus the damping.

•Speed: Higher speeds can lead to a change in the damping mechanism, potentially reducing it at very high speeds, according to SKF Evolution

Coefficient of friction for track rollers

https://medias.schaeffler.us/en/yoke-type-roller-bearing-track-rollers#23144110475

Type |

Coefficient of friction |

|

|---|---|---|

f |

||

Ball bearing, single row |

0.0015 |

to 0.002 |

Ball bearing, double row |

0.002 |

to 0.003 |

Friction coefficient μ, of bearing types

https://koyo.jtekt.co.jp/en/support/bearing-knowledge/8-4000.html

Bearing type |

Friction coefficient |

|---|---|

Deep groove ball bearing |

0.0010~0.0015 |

Angular contact ball bearing |

0.0012~0.0020 |

Self-aligning ball bearing |

0.0008~0.0012 |

Cylindrical roller bearing |

0.0008~0.0012 |

Full complement type needle roller bearing |

0.0025~0.0035 |

Needle roller and cage assembly |

0.0020~0.0030 |

Tapered roller bearing |

0.0017~0.0025 |

Spherical roller bearing |

0.0020~0.0025 |

Thrust ball bearing |

0.0010~0.0015 |

Spherical thrust roller bearing |

0.0020~0.0025 |