Cam Life

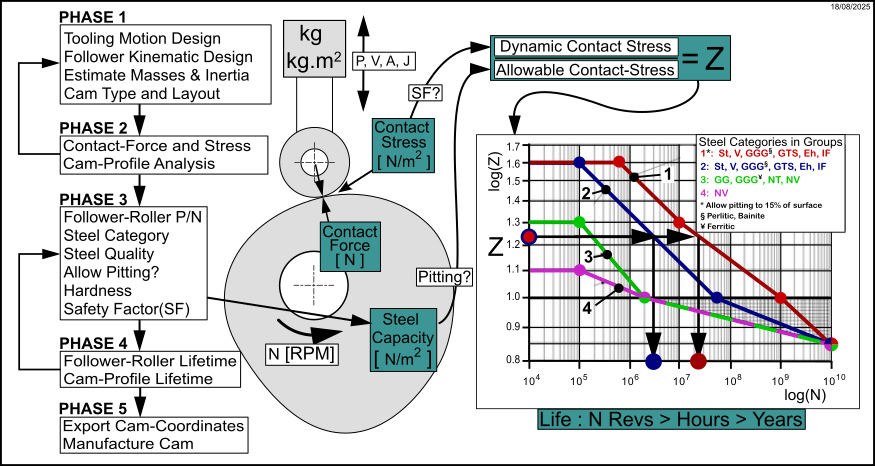

Work Flow - Phases to calculate the Cam Life.

Contact-Stress

To calculate the life of a Cam-Profile you first select a Follower-Roller in the Roller-Life tab. We can then calculate the contact-stress (Hertzian Stress), which is at the contact between the Cam-Profile and Follower-Roller.

To calculate the contact-stress we must first calculate the contact-force from the addition of Inertia, Spring, Friction, Gravitational, Coriolis, and other forces. The total force is usually different at each step in the machine-cycle.

The contact-stress is a function of the contact-force and also material and geometric factors

We calculate the contact-stress at each step of the machine cycle to find the Maximum Contact-Stress.

You can apply a safety-factor (see Parameters tab), which we use to calculate the Dynamic Contact-Stress.

Steel Capacity

Once we have found the Maximum Contact-Stress and Dynamic Contact-Stress, we must calculate the capacity of the steel - with which you propose to manufacture the cam - to resist contact-stress. The capacity of the steel is called the Allowable Contact-Stress of the steel.

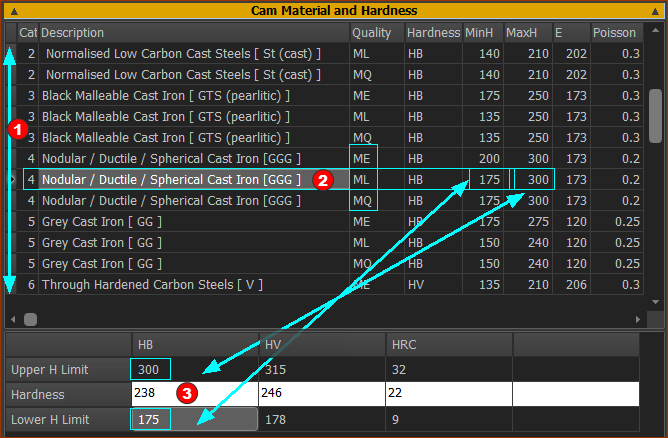

We calculate the Allowable Contact-Stress when you select a steel-category, its quality, and enter its hardness. You can also apply a factor to many of the steel-categories that allows up to 15% of pitting to the cam's rolling surface.

There are 14 cast and wrought steel-categories, each with 3 steel-qualities. Each steel category and quality has a maximum and minimum hardness which define the limits of the desired or actual hardness that you can enter.

Z-N Curve

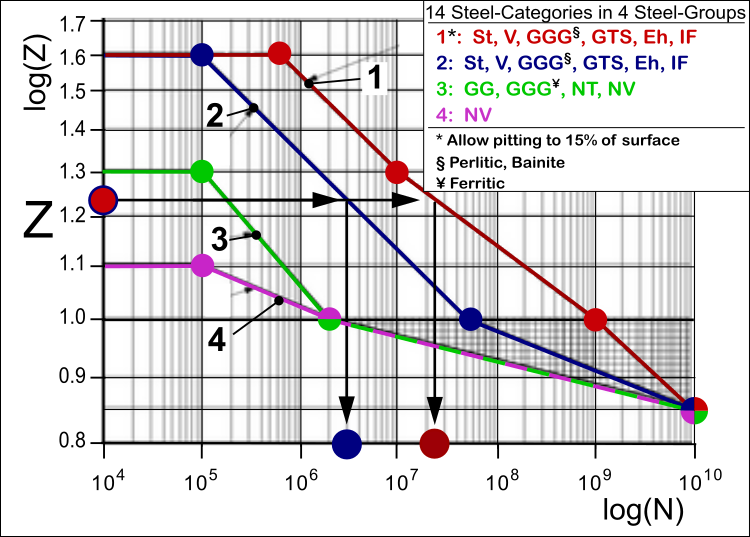

We group the 14 Steel-Categories into Steel-Groups 2, 3, and 4.

You can allow limited pitting to the Steel-Categories in Steel-Group #2, which becomes Steel-Group 1, which moves the Z-N plot to the right, to give the Z-N plot for “Life with Pitting”.

We calculate the parameter “Z” as the ratio of Dynamic Contact-Stress to the Allowable Contact-Stress.

We can then calculate, from the Z-N curve for the steel-category in a Steel-Group the number of machine-cycles, N, the steel can endure before rolling-contact fatigue results in pitting (or excessive pitting) and failure of the cam-surface.

Z-N Curves for different Steel Categories

Notes

Different steel categories have different Z-N curves.

1 × Life is at Z=1. The number of machine-cycles, N, for 1 × Life (Z=1) is different for different Steel-Groups.

2D-Cam > Cam Life tab

To Calculate Cam Life, you must :

Parameters tab

Cam Life tab

Review the Cam's Lifetime |

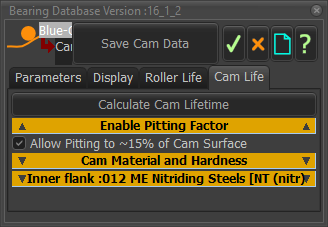

2D-Cam dialog > Cam Life tab

Cam Life: tab

Allow Pitting to ~15% of Cam Surface?

|

Enter the Hardness as HB, HV, or HRC Select a Steel Category and Quality

Enter the Steel's Hardness within the High and Low Hardness Limits

|

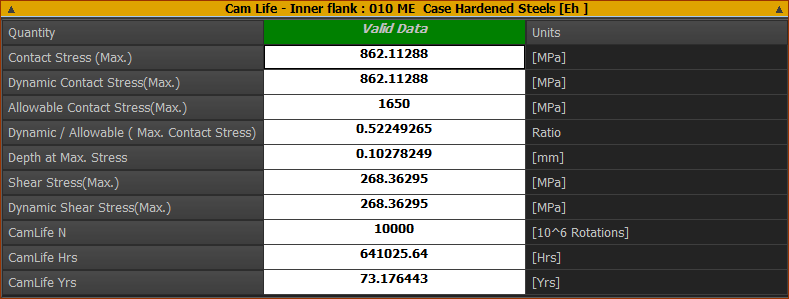

Cam-Life Results

NOTES ON CAM LIFETIME PLOTS

|

Steel Categories and Example Steels (mostly ISO 6336-5)

Examples Steels that PSMotion have assigned to the different steel and cast-iron categories. You must check that your steel is in the correct-category.

Steel / Cast Iron Categories |

Material Type (Abbreviation) |

Steel Quality |

Hardness Range |

Example Steels NOT from ISO 6336 |

|---|---|---|---|---|

Normalized Low Carbon Steels & Cast Steels (St (cast)) |

Wrought, normalized, Low Carbon Steels |

ML, MQ |

110 - 210 HB |

St50.2, 1.0050, E295 St60-2, 1.0060, E335 St70-2, 1.0070, E360 |

ME |

110 - 210 HB |

|||

Cast Steels |

ML, MQ |

140 - 210 HB |

GE200, 1.0420 GE240, 1.0446 GE300, 1.0558 |

|

ME |

140 - 210 HB |

|||

Cast Irons |

Black Malleable Cast Iron (pearlitic structure) (GTS (perl)) |

ML, MQ |

135 - 250 HB |

EN-GJMB-350-10 : HB 150 EN-GJMB-500-5 : HB 165-215 EN-GJMB-600-2 : HB 195-245 EN-GJMB-700-2 : HB 240-290 |

ME |

175 - 250 HB |

|||

Nodular Spheroidal Pearlitic Bainitic Ferritic Cast Iron (GGG (perl, bai, ferr)) |

ML, MQ |

175 - 300 HB |

EN-GJS-400-15 : HB 135-180 EN-GJS-500-14 : HB 170-215 EN-GJS-600-10 : HB 190-230 EN-GJS-700-2 : HB 210-305 EN-GJS-800-2 : HB 240-335 EN-GJS-900-2 |

|

ME |

200 - 300 HB |

|||

Grey Cast Irons (GG) |

ML, MQ |

150 - 240 HB |

EN-GJL-200, GG20 EN-GJL-300, GG30 EN-GJL-350, GG35 EN-GJL-400, GG40 |

|

ME |

175 - 275 HB |

|||

Through-Hardened Wrought Steels Nominally >0.2%C

|

Carbon Steels (V)

|

ML |

135 - 210 HV |

C40E, 1.1186 C45E, 1.1191, 1045,

|

MQ |

135 - 210 HV |

|||

ME |

135 - 210 HV |

|||

Alloy Steels |

ML |

200 - 360 HV |

42CrMo5, 1.7225 |

|

MQ |

200 - 360 HV |

|||

ME |

200 - 390 HV |

|||

Through-Hardened Cast Steels Nominally > 0.2%C

|

Carbon Steels (Low to Medium) |

ML, MQ |

130 - 215 HV |

100Cr6 |

ME |

130 - 215 HV |

|||

Alloy Steels |

ML, MQ, ME |

200 - 360 HV 200 - 360 HV |

G25CrMo4, G34CrMo4, G35CrNiMo6-6 G42CrMo4 :1.7231 |

|

Case Hardened Wrought Steels |

< 0.25%C (Eh) |

ML |

600 - 800 HV |

C14E/C10R/C15E/C15R/ 17Cr3 (1.7016, AISI 5115) 16MnCr5 (1.7131), 5115, 8620 18CrMo4 20MnCr5 (1.7147) 15NiCr13 (1.5752) 17CrNi6-6 (1.5918) 18CrNiMo7-6 (1.6587) 20NiCrMo2-2, 22CrMoS3-5 18NiCrMo5 17NiCrMo6-4, EN36 - 1.5752 - 14NiCr4, SAE8620, 14NiCrMo13-4, AISI 9310, 1.6657 655M13 EN39B(835M15), 15NiCrMo16-5, SNCM815. |

MQ |

660 - 800 HV |

|||

ME |

660 - 800 HV (58-64HRC) |

|||

Flame or Induction Hardened Wrought or Cast Steels |

>0.25%C

(IF) |

ML, MQ, ME |

485 - 615 HV 500 - 615 HV 500 - 615 HV |

34Cr4 (1.7033) (530M32) 41Cr4, 34CrNiMo6 43CrMo4(1.3563) |

Nitrided Wrought steels

Through Hardened, Nitrided |

Nitriding Steels |

ML |

650 - 900 HV |

EN40B, EN41B, 31CrMo12, 42CrMoV12, 38CrAlMo 31CrMoV9. 905M39 |

MQ |

650 - 900 HV |

|||

ME |

650 - 900 HV |

|||

Through Hardening Steels |

ML, MQ, ME |

450 - 650 HV 450 - 650 HV 450 - 650 HV |

32CrMoV13 |

|

Wrought Steels Nitro-Carburized |

Through Hardening Steels |

ML |

300 - 650 HV |

100CrMnSi6-4 (CarboNitriding) |

MQ |

300 - 450 HV |

|||

ME |

450 - 650 HV |

ML - limited demands on the material quality, number and type of inclusions, and on the material heat treatment process during gear manufacture.

MQ - requirements met by experienced manufacturers at moderate cost

ME - requirements realized when a high degree of operating reliability is required.

Refer to ISO 6336-Part 5 for ML, MQ, ME steels qualities.