A Chain-Link

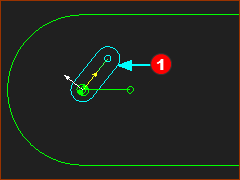

A Chain-Link moves along the path of the chain. The chain-link rotates as it moves around the arcs of each sprocket.

You will represent a Chain-Link with one of the two Parts in an R-P-R dyad.

The Sprockets

Note: We wrote this topic before the Add Pulley tool became available.

We add one rotating-Part to represent each Sprocket. Their centers are at the center of the arcs of the chain-path.

The sprockets - with 5 teeth - must rotate 12/5 times each time the chain cycles one time.

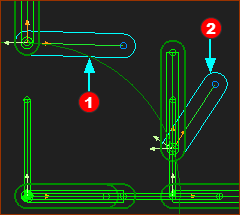

Add an R-P-R dyad to the Slider Sets

Remember, dyads always have two Parts and three Joints. Add an R-P-R dyad between Slider-Set 1 and Slider-Set 2 This dyad is: R(Pin-Joint) - P(Slide-Joint) - R(Pin-Joint) Top-Tip: Temporarily hide the Motion-Dimension FBs. See Display Filters: Hide Dimensions |

||||

|

STEP 1: Add two Parts and two Pin-Joints

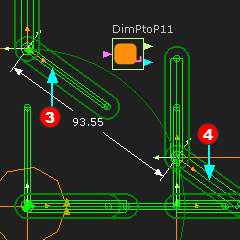

Pin-Joints are revolute joints. The Pin-Joints are the revolute joints (R) in the R–P–R dyad. STEP 2: Add a Slide-Joint

The Slide-Joint is the Prismatic-Joint in the R-P-R dyad. Part When you cycle the model, you will see the R-P-R dyad move with the Slider-Sets. STEP 3: Add a Measurement FB between the Pin-Joints

As you cycle the model you will see the dimension vary between 100mm an 93.55mm. |

|||

|

||||

Add the Sprockets

A Line for the Pulley on the Left.  The Part for the Pulley on the Left |

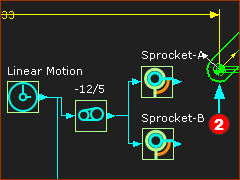

STEP 1: Add rotating-Parts for the sprockets

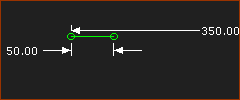

STEP 2: Rotate the sprockets at the correct speed Make a decision. For each machine-cycle, do you want: •the sprockets to rotate an integer number of times?, Or •the chain to cycle an integer number of chain-lengths? In this case we will move the chain one length in a machine-cycle. Each sprocket has 5 Teeth. We can use the Gearing FB to change the rotational speed of the sprockets. The ratio is –12/5 sprocket rotations for each 1 chain length of 12 Tool-Parts. The ratio is negative as the sprockets rotate clockwise.

|

||

Function-Blocks to rotate the Left and Right Pulleys at the correct speed. |