Cam Terminology:

Terms : |

Definitions |

|---|---|

Cam (or Cam-Part) : |

The Part to which you add the 2D-Cam to generate the shape of the Cam-Profile. |

Cam-Shaft : |

The most common Cam-Part. It is a rotating-Part (a shaft), to which you add the 2D-Cam (or 3D-Cam) as a Cam-Profile. A Cam-Shaft usually rotates with a constant angular-velocity. |

Cam-Profile : |

The shape of the 2D-Cam (or 3D-Cam). Its surface is in continuous contact with the Follower-Profile. |

Track-Cam or Groove-Cam : |

A groove that is cut into a Cam-Blank with an Outer and an Inner Cam-Profile. A Follower-Roller fits in the groove. |

Follower (or Follower-Part) : |

The Part that supports the Follower-Profile. |

Follower Kinematic-Chain (or Kinematic Mechanism) : |

The Follower-Part (and other Parts that you join to the Follower-Part) to move the Tooling, Tool-Part or End-Effector. |

Follower-Profile : |

The shape of a machine component that is rigidly connected to the Follower-Part. Its surface is in continuous contact with the Cam-Profile. |

Follower-Roller : |

A Follower-Profile that is cylindrical or barrel-shaped. It is rigidly connected to the Follower-Part. |

Flat-faced Follower : |

A Follower-Profile that is a flat surface. It is rigidly connected to, or integrated with, the Follower-Part. |

Translating Follower : |

A Follower-Part that slides along a straight axis. |

Reciprocating Motion : |

A Translating Follower with a non-progressive motion. |

Rotating Follower : |

A Follower-Part that rotates about a fixed axis. |

Oscillating Motion : |

A Rotating Follower with a non-progressive motion. |

Progressive Motion : |

A motion, usually followed by a Dwell, that moves the Follower-Part progressively in one direction. |

Non-Progressive Motion : |

A motion that returns the Follower-Part to its original position after each machine cycle. |

Indexing : |

A progressive motion, usually rotating. |

Indexer : |

A device whose input is a constant-speed (usually) Cam-Shaft and output is a rotating-Part with a progressive motion. The input rotates one time to index the output by the Index-Angle one time. The Index-Angle is such that 360º/(Index-Angle) is an integer. The Integer is also termed the Number-of-Stops of the Indexer. |

Cam-Blank : |

The material from which you cut the shape of the Cam-Profile. |

Force Closed Cam : |

An external Force (e.g. a Spring) holds the Follower-Profile against the Cam-Profile. The external Force must be greater than other forces that would lift the Follower-Profile off the Cam-Profile. |

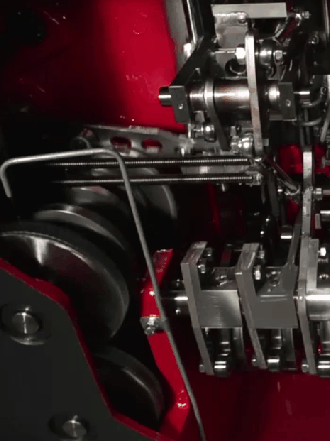

Body Closed Cam : |

Two Follower-Profiles are rigidly connected to one Follower-Part, which have contact with two different Cam-Profiles, also in one Cam-Part. The contact between one Follower-Profile and one Cam-Profile prevents the other Follower-Profile from moving away from the other Cam-Profile. |

Track-Cam or Groove-Cam : |

A type of Body Closed Cam in which a slot is cut into a Cam-Blank. One or two Follower-Rollers fit between the Outer-Flank and Inner-Flank of the slot. |

Introduction to the Cam Mechanical System.

|

The typical Cam Mechanical System has a: Simple Input-Motion Usually, the motion of the Cam-Part is simple. It is said to be the input-motion. Complex Output-Motion Usually, the motion of the Follower-Part is more complex. It is said to be the output-motion. Input-Transmission The mechanical components from the motor (power source) to the Cam-Part are said to be the input-transmission. Output-Transmission The mechanical components from the Follower-Part to the payload are said to be the output-transmission. Follower-Profile The element, connected to the Follower, that is in direct and continuous contact with the Cam-Profile. It is usually a Follower-Roller, and occasionally a Flat-faced Follower. Other more general shapes are possible, but rare. Payload : Other names for Payload are Load, Tooling, and End-Effector. |

|||||||||||||||||||||||||||||||||||

The design and selection of the mechanical components for the input-transmission and the output-transmission significantly affect the overall performance of the cam-system. The mechanical components are usually conventional machine-elements, such as shafts, gears, couplings, sliders, and linkages. They are usually connected together in series. You cannot design a cam in isolation of the other components in the mechanical system. The characteristics of the mechanical components that most significantly affect the performance of the Cam-System are the mass moment of inertia (or mass for linear systems), rigidity (or stiffness for linear systems), and backlash in the input-transmission and output-transmission. Motion-Design The motion you design for the payload is equally important. A poor motion will needlessly incite vibrations in any mechanical system. A good motion will give you a machine that lasts longer, jams less frequently, and has the same capital cost as a machine with poor motion-design. Motion-Design for a single axis is fairly straightforward. Motion-Design for multi-axis machines, with many interacting mechanisms and complex material-to-machine interactions, requires experience, skill and a good understanding of the motion-design requirements as a whole. Cam Mechanism : from the 'Power-Source' to the 'Payload'

|

||||||||||||||||||||||||||||||||||||