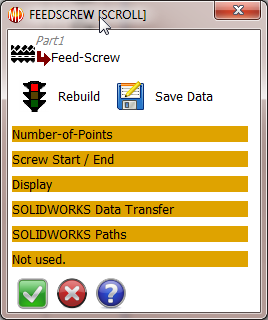

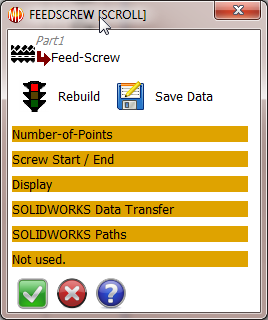

Feedscrew ( Scroll)

See Add Scroll

We have labeled the dialog as Feedscrew and Scroll because they are both common terms.

Other terms include: Worms, Infeed Screws, Gusanos, and Tortillas sin fin.

Use the Feedscrew (Scroll) dialog to:

•Set the number-of-points along the feedscrew surface for each 'rim'

•Set the Start and End - the 'range' - of the 3D-Cam

•Edit the display of the feedscrew in the graphics-area

•Export the feedscrew to SolidWorks®

•Rebuild the feedscrew with the current or active settings.

•Save the feedscrew data that defines the surface mesh.

To Open the Feedscrew dialog

Feedscrew dialog

|

Buttons at top of dialog

Rebuild and Save Data buttons

•Use the Rebuild button to

ore-calculate the points along each 'rim' when you change a parameter

obefore you use the Save Data button

obefore you transfer the Feedscrew to SolidWorks

•Use the Save Cam button to save the feedscrew mesh data as text files.

|

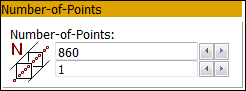

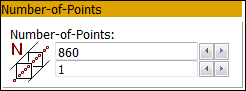

Number of Points

|

Preamble:

•We specify a Feedscrew with a surface.

•There are a number of lines, that we call Rims, along the feedscrew surface.

•There is one Rim for each Motion-Point as defined by the Motion-Path FB.

•There are a number-of-points along each Rim.

Parameters:

Number-of-Points:

Number-of-points along each Rim. - 860 in dialog to left

|

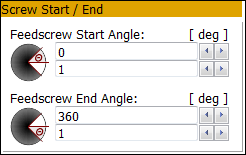

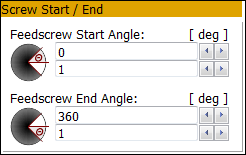

Screw Start/End

|

Preamble:

When you add a Feedscrew, we calculate for you the surface for a complete cycle of the MMA : 0 – 360

Use this separator to edit the range of the MMA for which you want to calculate the feedscrew.

The Number-of-Points along each rim does not change.

Parameters:

Feedscrew Start-Angle

•Edit the Start-Angle

Feedscrew End-Angle

•Edit the End-Angle |

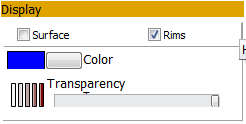

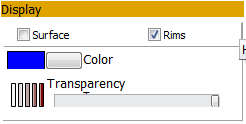

Display

|

Preamble:

The 'MechDesigner Display' edits how the surface of the Feedscrew shows in the graphics-area.

Controls:

'Surfaces' ; 'Rims' check-boxes

Use the check-boxes to Show or Hide Surface, and Show or Hide Rims.

Solids: show or hide, with the color in the 'color' control, and with the Transparency given by the 'Slider'.

Rims: show or hide the Rims along the Feedscrew.

Color

•Use the Windows color picker to select a color for the Feedscrew and Rims.

Transparency

•Use the slider to change the Transparency of the Feedscrew.

|

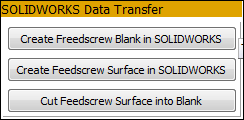

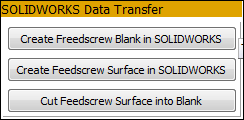

SOLIDWORKS Data Transfer

|

Preamble: When you have set the correct parameters in this dialog: Number-of-Point and Start/End Angles, then you can export the Feedscrew to SolidWorks. To do this

1.Open SolidWorks

2.Add and Save a new Part

3.Make sure the new Part is the 'active' document in SolidWorks

Buttons:

Create Feedscrew Blank in SolidWorks

•We export for you the sketch of the Feedscrew Blank and its Axis-of-Rotation'

•We instruct SolidWorks for you to use the Feedscrew Blank and Axis to add a 'Revolved' feature

Create Feedscrew Surface in SolidWorks

•We export for you the XYZ data of each Rim to a 'Curve' feature

•We instruct SolidWorks for you to use the Curves to Insert a Boundary Surface feature.

Cut Feedscrew Surface into Blank.

•We instruct SolidWorks for you to cut the Revolved feature with the Boundary Surface

See Troubleshooting below.

|

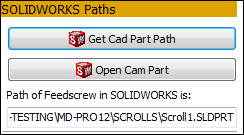

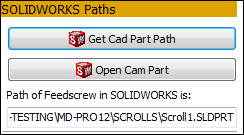

SOLIDWORKS Paths

|

Preamble:

After you have sent the Feedscrew to SolidWorks, it is often useful to link the its file-name in SolidWorks with the Feedscrew element that is in MechDesigner. At a later date, when you open this Feedscrew dialog again, you can reopen the part in SolidWorks.

Buttons:

Get Cad Part Path button: Click this button to link the CAD file-name in SolidWorks with the Feedscrew.

The file-name, with its full path, is put into the 'Path of Feedscrew in SolidWorks is :

Open Cam Part button: Click this button to open the part with the file-name in the 'Path of Feedscrews in SolidWorks is' box.

Before this is possible:

1.You have previously transferred a Feedscrew to SolidWorks and saved the file,

AND

2.You have already clicked the button 'Get Cad Part Path' button. |

|

|

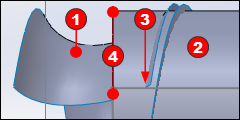

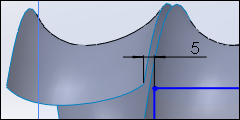

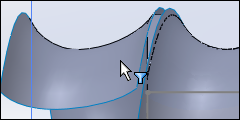

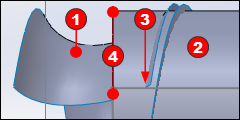

The last command: 'Cut Feedscrew Surface into Blank'  may not work. may not work.

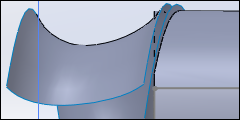

CHECK 1: In SolidWorks, inspect the length of the Scroll Blank relative to the Scroll-Surface relative to the Scroll-Surface . .

In the image to the left, the left of the Scroll-Blank is to the left of the end of the Scroll-Surface is to the left of the end of the Scroll-Surface . .

In this case, the 'Cut Scroll Surface from Blank' (button in dialog) does not work. in dialog) does not work.

|

|

You must, in SolidWorks, or MechDesigner

1.Edit the sketch of the Scroll-Blank

I prefer to edit the sketch in SolidWorks.

|

|

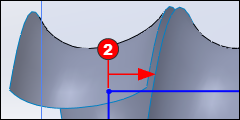

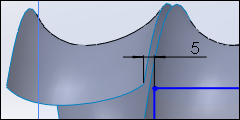

2.Move the end of the sketch to the right of the end of the Scroll-Surface.

In this sketch, I have added a dimension between the end of the Scroll-Surface and the left of the Sketch-Blank.

|

|

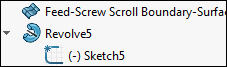

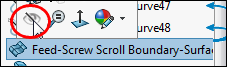

To help, I have, in SolidWorks, dragged the 'Revolve' feature to below 'Feed-Screw Scroll Boundary-Surface'.

Then, as I edit the sketch for the Sketch-Blank I can see the end of the Scroll-Surface.

|

|

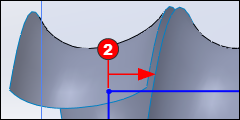

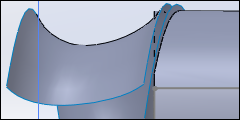

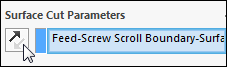

CHECK 2: After you close the sketch and rebuild the model. the Surface-Cut feature in SolidWorks might cut to the incorrect side of the Scroll-Surface - see image to the left. In this case:

|

|

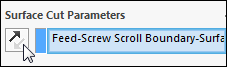

1.Edit the Feed-Screw Scroll Boundary-Surface feature in SolidWorks

2.Click the direction arrow - see image- to reverse the direction of the Cut. |

|

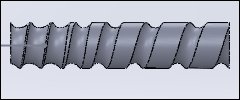

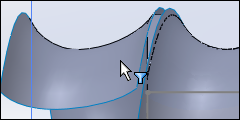

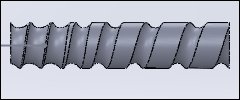

In the image, you can see the Scroll-Blank has been cut correctly by the Scroll-Surface.

However, the Feed-Screw Scroll Boundary-Surface feature is still shown in the model

|

|

CHECK 3: Edit the Feed-Screw Scroll Boundary-Surface feature to hide it from the display.

See image.

|

|

Finally, the scroll is correct.

|

Trouble-shooting the Feedscrew in SOLIDWORKS

Trouble-shooting the Feedscrew in SOLIDWORKS