Polynomial-Fit FB

See also: Add Polynomial Fit FB

Before you use this tool, we recommend you save your work.

Then save it again with a new model file-name.

About Polynomial FB

|

The Polynomial Fit FB finds a concatenated series of Polynomials (5th order) that are approximately equal to the data at its input-connector. After you do a Polynomial-Fit, you can: •Transfer Polynomials directly to MotionDesigner as a new Motion name-tab. •Connect a wire from the output-connector of the Polynomial-Fit FB to the input-connector of a different FB. •Export the motion-values that you calculate as a text-file. •Export the values for position, velocity, and acceleration at the beginning and end of each polynomial segment as a CSV file. •Export the polynomials segments in a format suitable for the Schneider-Electric EPAS4 servo-controller. |

How to open the Polynomial-Fit dialog

|

To open the Polynomial-Fit dialog:

|

The Polynomial-Fit dialog is now open.

Polynomial-Fit dialog

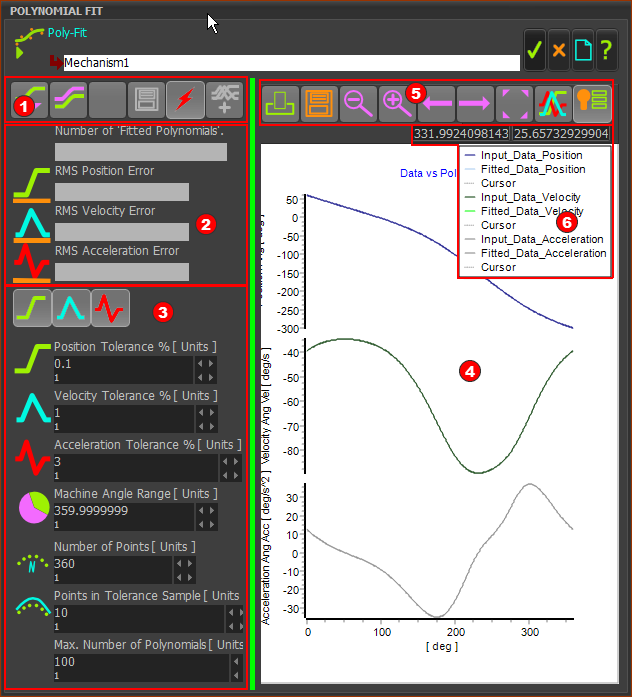

Polynomial-Fit FB dialog/interface. |

|

The Polynomial-Fit dialog:

|

Acquire and Save toolbar

Acquire and Save toolbar

Acquire and Save Results toolbar |

|

The toolbar buttons are:

|

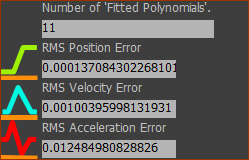

Analysis of Results

Analysis of Results

|

Number of Polynomials in Fit (read-only) The actual number of Polynomials we fit to the data at the input-connector. See also: Maximum Polynomial Count in the Settings for Polynomial Fitting Algorithms. RMS Position Error, RMS Velocity Error, RMS Acceleration Error (read-only). The RMS (Root-Mean-Square) error as a percentage, for each motion-derivative, between the Polynomials we fit and the data at the input-connector. |

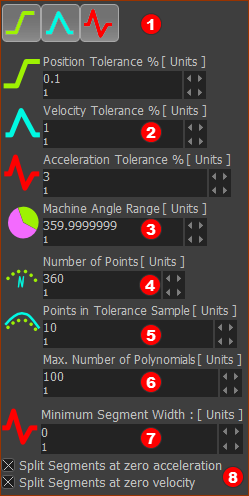

Settings for Polynomial Fitting Algorithms

Settings for Polynomial Fitting Algorithms

|

|

Parameters to enter before you click Fit Polynomials to Data (button

|

Graph toolbar

Graph toolbar

|

|

The toolbar buttons are:

|

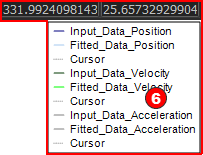

Graph Legend

Graph Legend

|

Graph plot color scheme for •original, or input, data •fitted data calculated from the fitted polynomials •each motion-derivative •Cursor - you can click ON a graph of each motion-derivative to show a cursor. The X-Y data-values of the active cursor is above the graphs. |