Machine-Settings

Use Machine-Settings to edit:

•Machine Speed

•Number-of-Steps (in one machine-cycle)

•Engineering Units

|

Click Edit toolbar > Machine-Settings OR Click Edit menu > Machine-Settings |

|

Machine-Settings dialog is now open.

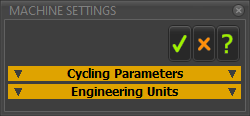

Machine Settings dialog

Machine Settings dialog

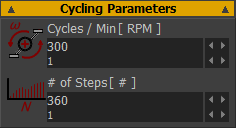

Cycling Parameters |

Cycles ∕ Min: (RPM) ( See also Note 1 ) RPM - Revolutions per Minute. - the model's Simulation-Speed. - the rate-of-change of the Master-Machine-Angle. MotionDesigner uses RPM to calculate the velocity, acceleration, and jerk values of the motion in each Motion name-tab Number-of-Steps: ( See also Note 2 ) Notes: •number-of-steps and Cam Accuracy - no relationship. Use the Cam-Coordinates dialog to calculate and save the Cam-Coordinates with any number of points and accuracy. •Number-of-Steps is the number of facets along a Cam in the graphics-area •Number-of-Steps is the number of points along each graph - see Graph FB •Number-of-Steps is the number of points along the curve of a Trace-Point - see Add Trace-Point •Number-of-Steps is the number of points/dots on the Motor Torque and Speed Curves •Usually, 120 is good. More than 360 is not usually needed. See also: Run menu > Step Forward / Step Backward |

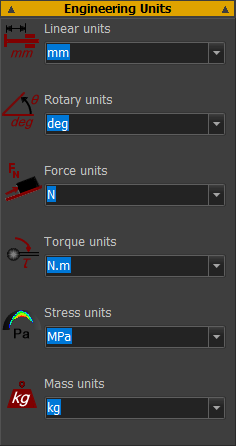

Engineering Units |

||||||||||||

Engineering Units : ( See also Note 3 )

|

More about Machine Settings parameters.

|

Cycles ∕ Min does not change the animation-speed. Change the animation-speed with the Animation Speed Slider. Do NOT increase Machine-Settings >Number-of-Steps to increase the accuracy of your model or a 2D-Cam. Use the Cam-Coordinates dialog to increase the accuracy of a 2D-Cam you export for manufacture. Number-of-Steps = 120 is ideal. 360 should be the maximum, for nearly all models. To move the model with small steps (increments), we recommend you use the Spin-Box in the Master Machine Angle. If you change the dimension units, you do not change the size of the model. For example: 100 mm is 3.94 inches if you change dimension units from mm to inches. For example: 100 degrees is 1.75 radians if you change dimension units from degrees to radians. In all cases, we do not show you the units in the graphics-area. |