Cam-Data FB > Cam-Coordinates

See Add Cam-Data FB

Use a Cam-Data FB to calculate Cam-Coordinates for the Cam-Profile.

Calculate the Inner, Outer, and/or Pitch-Center Cam-Profiles as: •XY-Points Export a Cam-Profile directly to SolidWorks as XY-Points or BiArcs. Save the Cam-Coordinates to your hard-drive with these file types: •.TXT - XY-Points or BiArcs •.CSV - XY-Points or BiArcs - see Note •.DXF - XY-Points or BiArcs •.SLDCRV (import to SOLIDWORKS for a “Curve through XYZ Points” feature) •.STP : see Options for: Save Cam as a STEP file Notes CSV delimiter (List Separator) - see Application-Settings > Number Format tab > Data Output Format > List Separator / Delimiter Option In the 2D-Cam dialog > Parameters tab > Cam Range and Radius separator, there are two parameters: Cam-Start and Cam-Range. Cam-Start These edit the first Cam-Coordinateyou edit the range of the MMA over which to calculate the cam. You can also edit the start of the cam (relative to the MMA) We calculate for you and export the Cam-Coordinates: •from Cam-Start (default = 0) to Cam+Start + Cam-Range (default = 360) Edit the 2D-Cam to edit Cam-Start and/or Cam Range - see 2D-Cam dialog - Parameters tab. |

2D-Cam Work-flow

Action |

Help Topic |

|---|---|

Before you start this work-flow: add a kinematic-chain for the Cam-Part and a kinematic-chain for the Follower-Part; add mass-properties to the Parts; develop the motion design. The two kinematic-chains must be kinematically-defined. |

|

1.Add a 2D-Cam; or if Conjugate Cams then 2 × Follower-Rollers and 2 × 2D-Cams; or if a Groove-Cam then two concentric (co-axial) Follower-Rollers with one for the Inner-flank only, and the one for the Outer-flank only. |

see Add 2D-Cam |

If the new 2D-Cam is one of two Conjugate-Cams, or it is one flank of a Groove-Cam, then: |

|

i.Add a Conjugate-Cam FB ii.Open the Conjugate-Cam dialog and select the one flank each from two 2D-Cams |

|

2.In the Kinematics-Tree, select the 2D-Cam or a Conjugate-Cam FB as the Power Source for the kinematic-chain that includes the Follower-Part |

|

3.Edit the 2D-Cam: to open the 2D-Cam dialog: review Display, Properties, Roller-Life, Cam-Life tabs |

see 2D-Cam dialog |

4.Add a Cam-Data FB |

see Add Cam-Data FB |

5.Edit the Cam-Data FB to link it to a 2D-Cam - close the dialog |

see Cam-Data dialog |

6.Connect wires from the output-connectors of the Cam-Data FB to a Graph FB |

|

7.Open the Graph FB to analyze the 2D-Cam: Contact-Force, Maximum Shear-Stress, Radius-of-Curvature, Pressure-Angle, Sliding-Velocity. |

|

8.Edit the Cam-Data FB again to calculate the Cam's Coordinates |

|

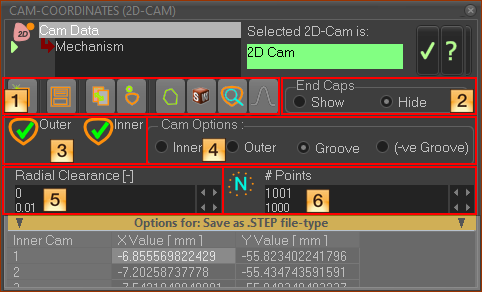

Cam-Data dialog: Cam-Coordinates

If you see “Select a Cam to activate this form”, then click a 2D-Cam in the Assembly-Tree or graphics-area to link it to the Cam-Data FB - see Cam-Analysis |

|

or

See also: Options for: Save as STEP file-type . |

Click icon

|

||

|

|

Clear ALL coordinates from the table |

|

|

Save Cam-Coordinate data as: •STP(STEP)- •DXF •CSV •TXT •SLDCRV (SOLIDWORKS Curve file, tab delimited ) - XY Points + Z-data = 0 Note: If this icon is not enabled, make sure Plate-Radius is larger than the Maximum Radius of the Outer Cam. OR: Click Inner or Outer to recalculate the Cam-Coordinates of the Cam-Profile, then, click Inner or Outer again, to calculate the Cam-Coordinates of the Cam-Profile you actually want. See STEP File Options. |

|

|

Copy the Cam-Coordinates to your clipboard |

|

If Cam Option in |

|

|

|

Calculate Cam-Coordinates for the Inner Cam-Profile. Calculate Cam-Coordinates for the Outer Cam-Profile. Calculate Cam-Coordinates for the Pitch-Curve (XY-Points only). |

|

Click |

|

|

|

Calculate as XY-Points You enter the # Points We calculate the XY Coordinates of the Cam-Profile for the number-of-Points at equal increments of the Master Machine Angle. |

|

Calculate as BiArcs (see BiArcs) You enter the BiArc Error We calculate the BiArcs so that the maximum error between the cam we calculate and the true Cam-Profile (we also calculate!) is less than, or equal to, the BiArc-Error. |

|

|

Before you click this button, make sure that SOLIDWORKS is open and the active SOLIDWORKS document is a part document (.SLDPRT). |

|

|

|

We export the BiArcs to SOLIDWORKS as Arc sketch entities, OR We export the XY-Points to SOLIDWORKS and instruct SOLIDWORKS to use the XY-Points to add a Curve feature. In a SOLIDWORKS sketch, you can use Convert-Entities to convert the Curve feature to a Spline sketch entity. See also Note 4 |

|

Usually, we calculate for you the XY Points automatically Usually, we calculate for you the Bi-Arcs automatically, but it takes more time to complete. If the Traffic-Light is RED, click the Traffic-Light icon again. |

|

|

|

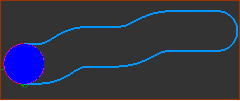

Display a preview of the Cam-Profile. |

|

|

Read-only - the cam is “Open” or the cam is “Closed”. |

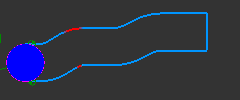

End Caps relate only to Slot-Cams, also known as Linear-Cams, or Ramp-Cams. Top-Tip - Save a Slot-Cam as a STEP file if it will not transfer to SolidWorks. |

|

End-Caps - Show |

Show or Hide End-Caps |

End-Caps work well when the independent axis to the Follower moves in one direction only - see image “End-Caps - Show” If the independent axis changes its direction in the middle of its travel, you see False End-Caps in the middle of the Slot-Cam. - see image: “Slot-Cam with 'False' End-Caps”. Before you export Cam-Coordinates we recommend you add a dummy slot-cam - and move the main axis of the Slot-Cam in one direction at Constant-Velocity, over one machine-cycle. To make sure the Constant-Velocity is correct: 1.Connect a wire from a Linear-Motion-FB to a Gearing FB 2.In the Gearing FB, enter a Gearing Ratio = Linear Travel distance of Slot-Cam / 360). 3.Connect a wire from the Gearing FB to the Motion-Dimension FB as the motion of the Slot-Cam. As the MMA increases from 0 to 360, the Cam travels from 0 to Maximum Travel distance of Cam (mm). |

|

Slot-Cam with 'False' End-Cams |

|

End-Caps - Hide |

|

|

The cam-coordinates have been calculated. The Radius of the Follower-Roller × % Cam RoC Soft-Limit is greater than the minimum Radius-of-Curvature - see 2D-Cam dialog |

|

The cam-coordinates have not been calculated - Usually after you change from # Points to BiArc Error, or vice-versa. |

|

It is not possible to calculate the cam-coordinates correctly, Possibly because of undercutting. |

|

The cam-coordinates have been calculated. The Radius of the Follower-Roller × % Cam RoC Soft-Limit is less than the minimum Radius-of-Curvature - see 2D-Cam dialog - Undercutting is possible. |

Calculate, Display, and/or Save the Cam-Coordinates: |

|

|

•Inner Cam-Profile ONLY |

|

•Outer Cam-Profile ONLY |

|

•Groove-Cam If you select Groove-Cam AND if you toggle |

|

•Negative-Groove The Negative-Groove option applies only when you save the Cam as a STEP file-type - see The STEP file is the space filled by the path of the Follower-Roller along the Cam-Profile (plus Radial Clearance). Note: This is not the same as a Rib Cam. You need to model a Rib-Cam with Follower-Rollers, with one each side of the Rib. |

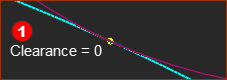

Example Radial-Clearance  Cam with 0.2mm Radial Clearance |

See also : 2D-Cam dialog > Parameters tab > Cam Range and Radius Radial Clearance (mm) Default = 0 , Negative or Positive Positive Value - we re-calculate the cam for you to give a clearance between the Follower-Profile and the Cam-Profile. AND: Negative Value - we re-calculate the cam for you to give an interference between the Follower-Profile and the Cam-Profile. |

Applications: Groove-Cam - add clearance (Positive Value) for a Follower-Roller in a Groove cam-type (See Note ) Conjugate-Cam - to add a small clearance (Positive Value) to compensate for tolerances in the cam assembly. Rough-Cut - to oversize an Inner-Cam or undersize an Outer-Cam for a Rough-cut. Radial-Clearance should be a Negative-Value Note: Frequently, Stud-type Follower-Rollers have a dimensional tolerance negative bias - for example, . You may consider that to be enough clearance. |

|

Max Chord-Error with BiArcs |

Apply this maximum BiArc-Error between the Cam-Profile we calculate with BiArcs and the true cam-profile. |

Number of XY Points |

Calculate these number of points for the Cam-Profile at equal increments of the Master-Machine Angle. |

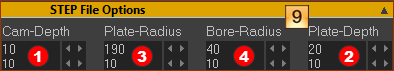

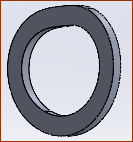

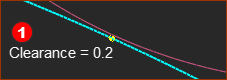

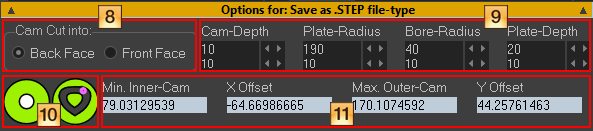

Options for: Save as .STEP file-type

Edit these parameters before you save a cam as a STP (STEP) file.  |

|

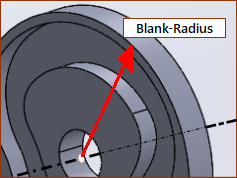

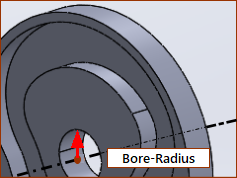

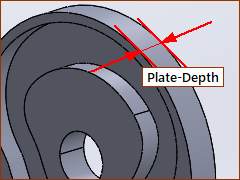

![]() Dimensions for STEP file ONLY

Dimensions for STEP file ONLY

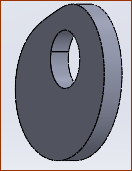

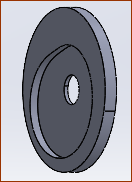

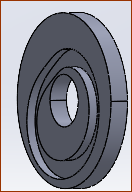

These images show the features of a Groove-Cam that has been exported and opened in SolidWorks:

|

|

|

The depth of the Groove Cam cut into the Cam-Plate. The width of the Cam-Flanks. Minimum Plate-Depth – Cam-Depth ≥ 2 mm |

|

The radius of the Cam-Plate, when you select: Outer or Groove-Cam |

|

The radius of the hole through the center of the Cam-Plate |

|

The total depth, or thickness, of the Cam-Plate. |

![]() Schematics of Cam type; Are the Dimensions OK or Not-OK?

Schematics of Cam type; Are the Dimensions OK or Not-OK?

Status of Cam, Blank-Radius and Bore-Radius relative to Cam-SizeThe Plate-Radius The Bore-Radius |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

You can save the STEP file. |

|

You can NOT save the STEP file. |

|

|

|

You can NOT save the STEP file. |

|

You can save the STEP file. |

|

|

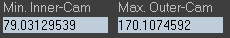

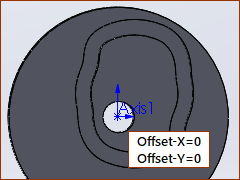

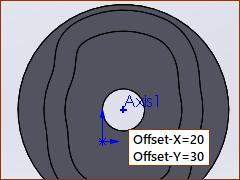

![]() Minimum/Maximum Radius of Cams, Offset X and Offset Y.

Minimum/Maximum Radius of Cams, Offset X and Offset Y.

•Min Inner-Cam - Minimum radius of Inner Cam •Max. Outer-Cam - Maximum radius of Outer Cam (see also  These values are useful to know when you want to make sure there is a minimum difference between the: •Bore-Radius and the minimum radius of the Inner Cam. •Plate-Radius and the maximum radius of the Outer Cam. X-Offset and Y-Offset When the Cam is stationary, enter an X-Offset and Y-Offset to move the center of the Cam-Plate relative the 0,0 of the Mechanism-Plane / Base-Part.

|

|

|

X Offset = 0, Y Offset = 0 Read-only if the Cam is a not stationary.

Image left: Blank-Radius and Blank-Bore with X-Offset = 0 and Y-offset = 0 |

|

X Offset = 20, Y Offset = 30 Image left: Blank-Radius and Blank-Bore with X-Offset = 20 and Y-offset = 30 The maximum radius of the Blank-Bore can be increased, and the minimum radius of the Blank-Radius can be decreased. |

Notes: