Dynamics of Cam Mechanical Systems

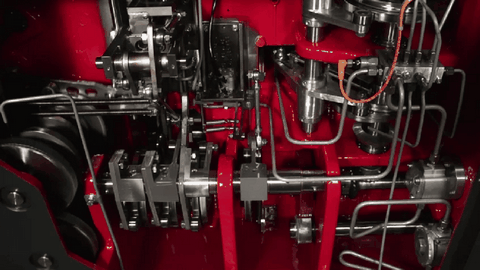

Example Cams in an enclosure with forced oil lubrication

The Cam Mechanical System includes all of the mechanical components from the Power Source (usually the Servo or AC Motor) to the Payload.

MechDesigner calculates the Application-Load or Torque that a motor must provide to move each mechanisms with the motion you have designed for it with MotionDesigner. MechDesigner also calculates the active and reactive forces at each joint as they move.

These forces and torques are called kinetostatic-forces. It is important to know that kinetostatic-forces do not consider the parasitic effects of rigidity, vibration, backlash, friction, stiction, speed variation at the drive motor ... and more.

These parasitic effects will mean the motion of the payload is not exactly the same as the motion you have designed. A poor design will lead to greater differences between your motion design and the actual motion at the output - the payload.

This section reviews the parasitic effects on the performance of Cam Mechanical Systems. We also suggest how to improve your designs.

There is an emphasis on the Traditional Motion-Laws that are applied to mechanisms with Dwell-Rise-Dwell type motions. This is because their causes and effects on the mechanical system are easier to understand, and we obtain valuable design insights. You should be able to apply these insights even when you need to design a complex motion for a complex mechanism.